Next up is an I-7 built from a Athearn/Roundhouse old time 2-8-0 I picked up at the same show I got the 4-4-0 which is now the D-8. There are a couple ways to do this class of engine. There is the low set key hole firebox boiler version, the higher set wagon top slide valves, and the wagon top with piston valves. They are not highlighted very much but there were quite a few of these engines roaming the system.

To keep in my 30s-50s range I went with doing one of the later style versions of the class. Originally planning on keeping it slide valve, I changed my mind to do piston valve cylinders, mostly because I have not done a slide valve to piston valve conversion, so it was something new to try.

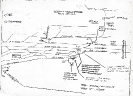

With all the variation in the large class this is basically what I'm going for.

This is the untouched Roundhouse engine.

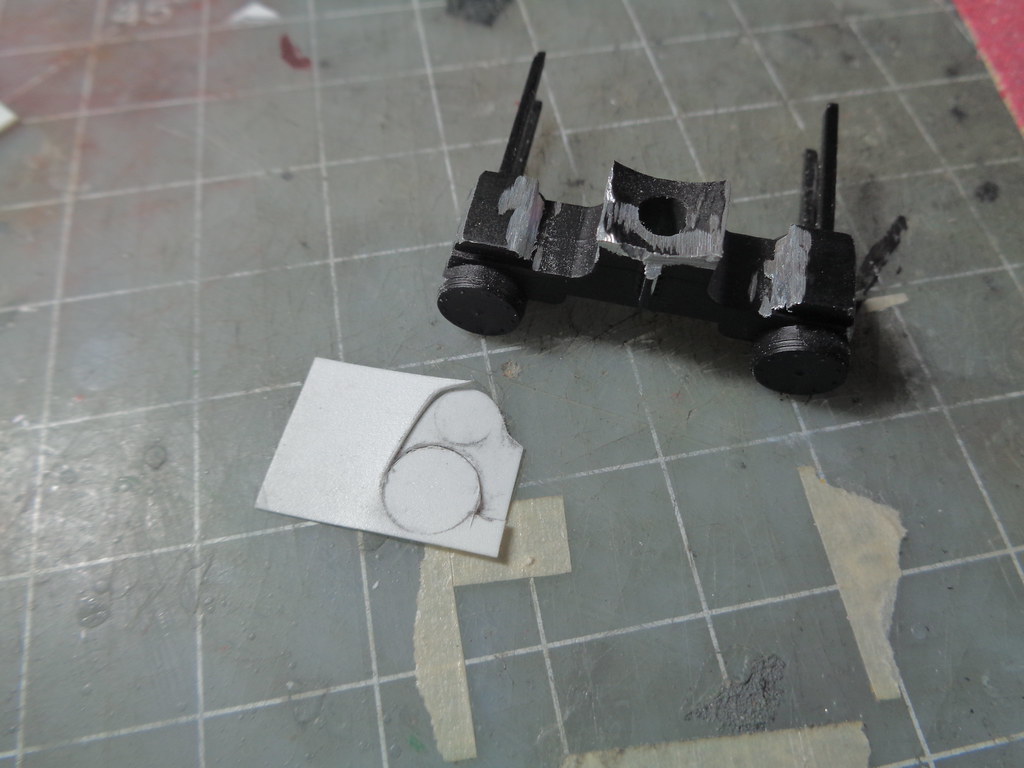

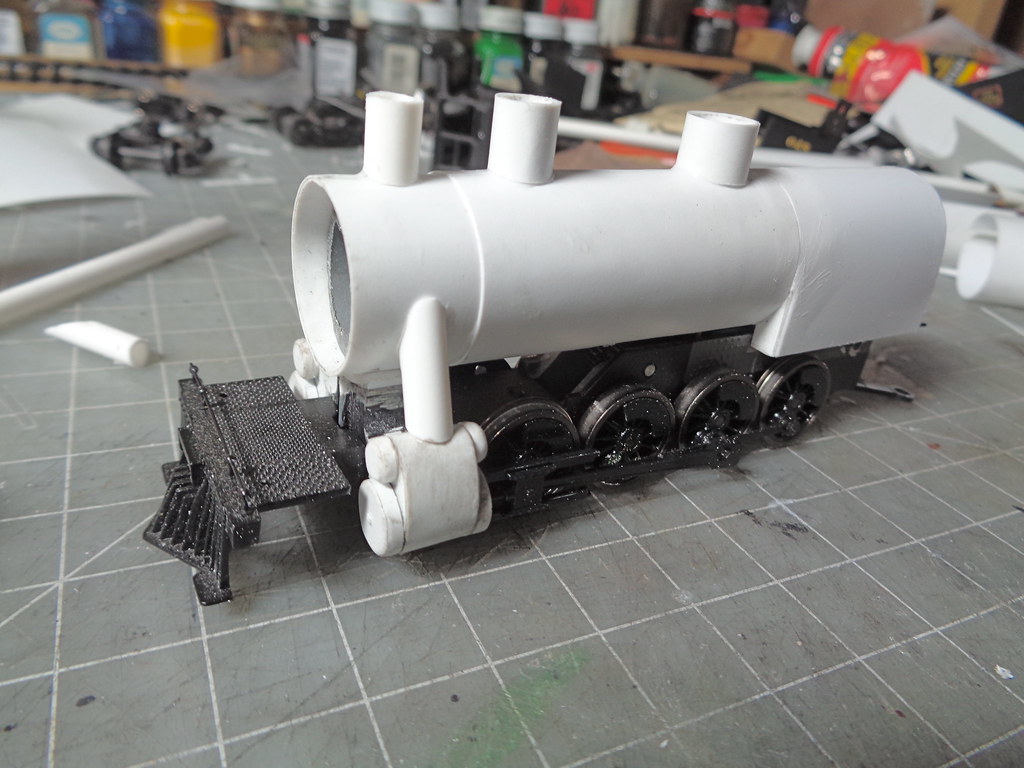

The engine was quickly broken down to what is needed for the project.

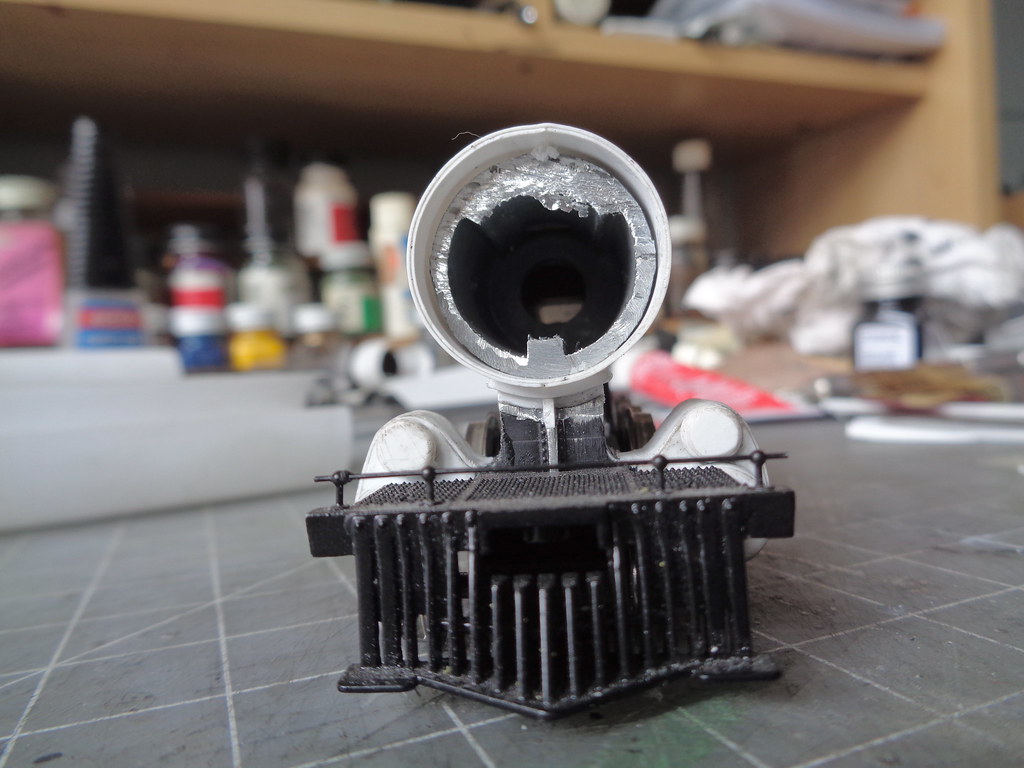

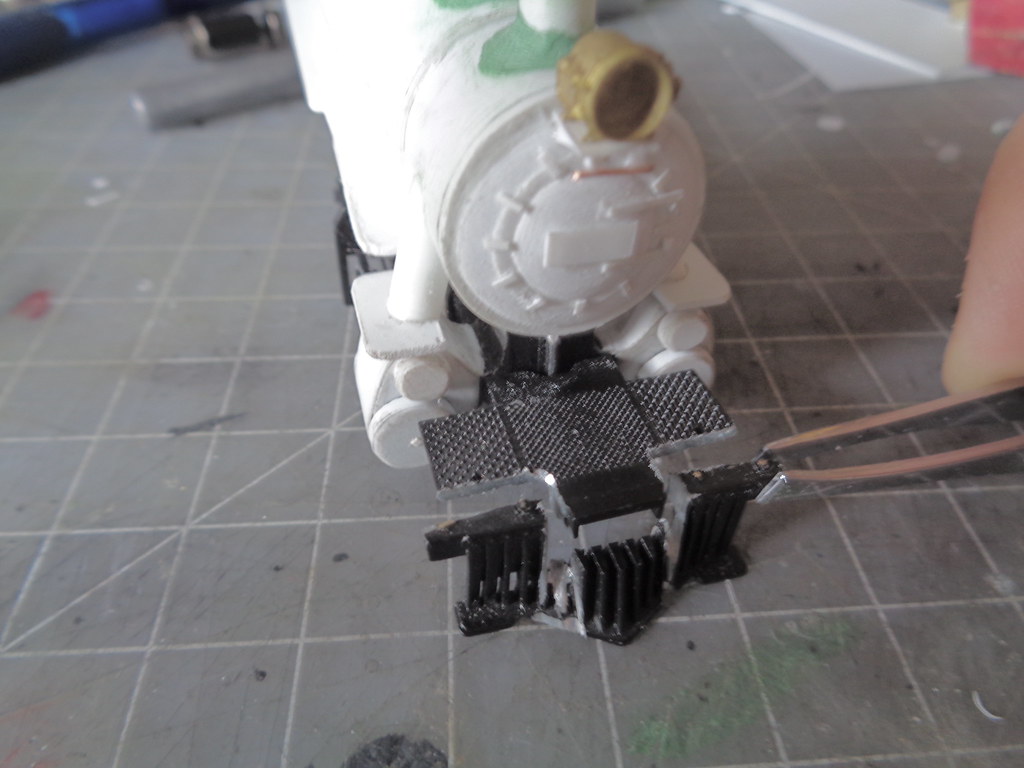

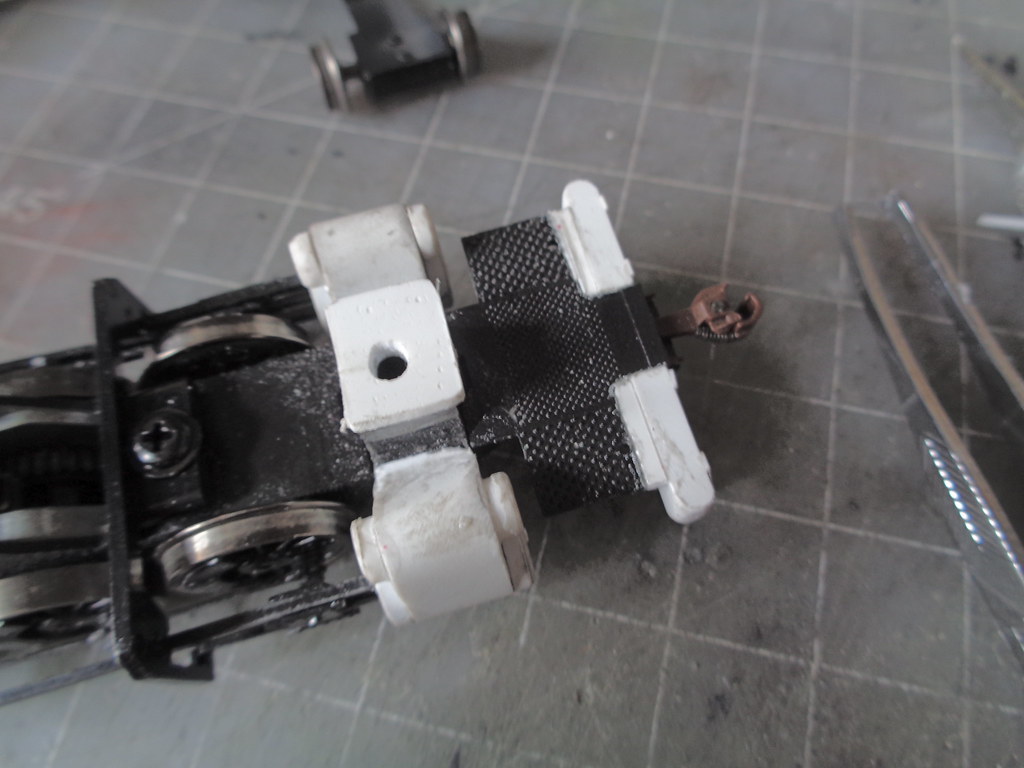

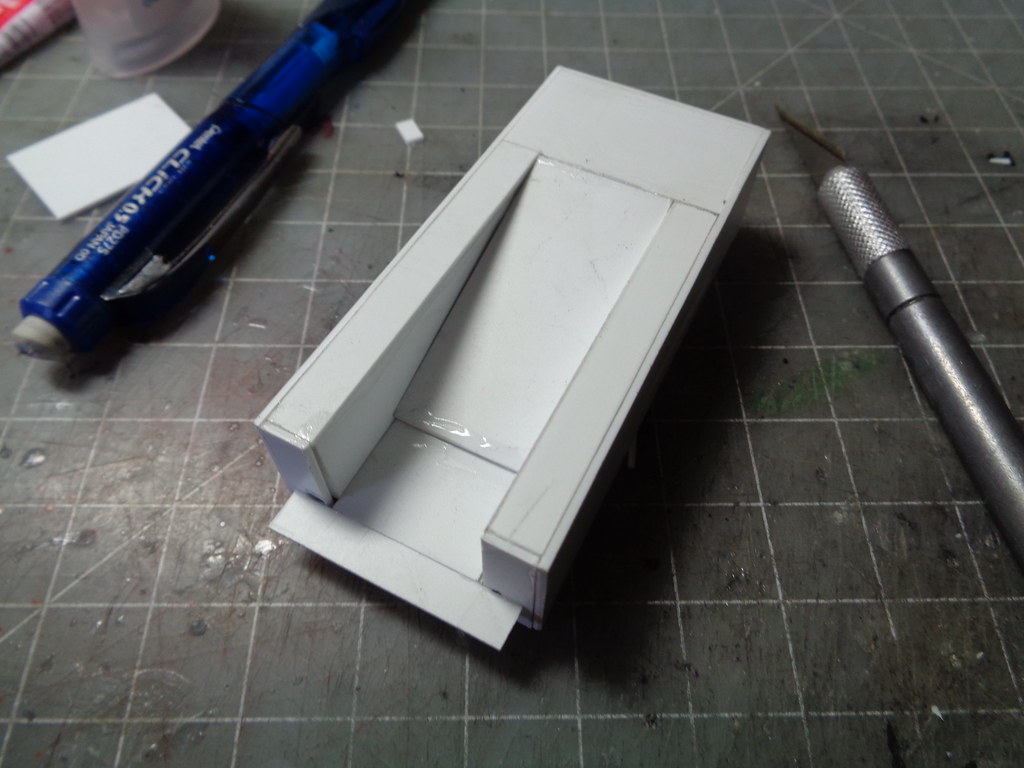

Piston valve cylinders lean in a little on this class so the slide valve casting was ground down a bit on the outside then the inside of the box on top of the main cylinder. The saddle for the boiler was also ground down in preparation of an extension that will lift the boiler up.

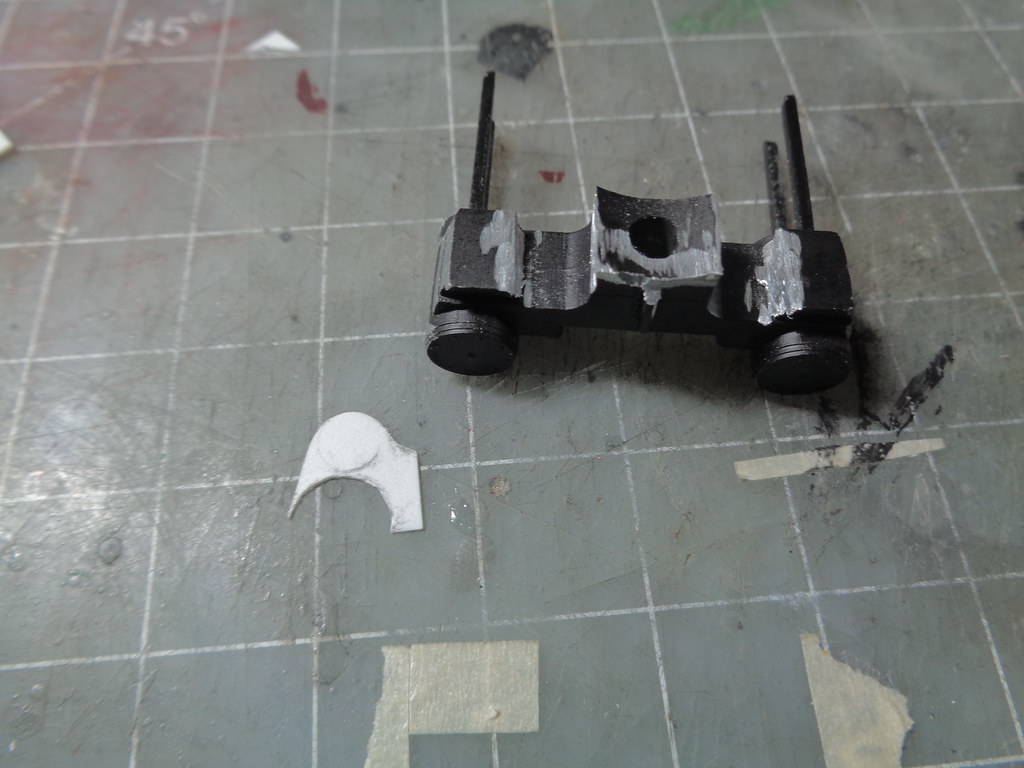

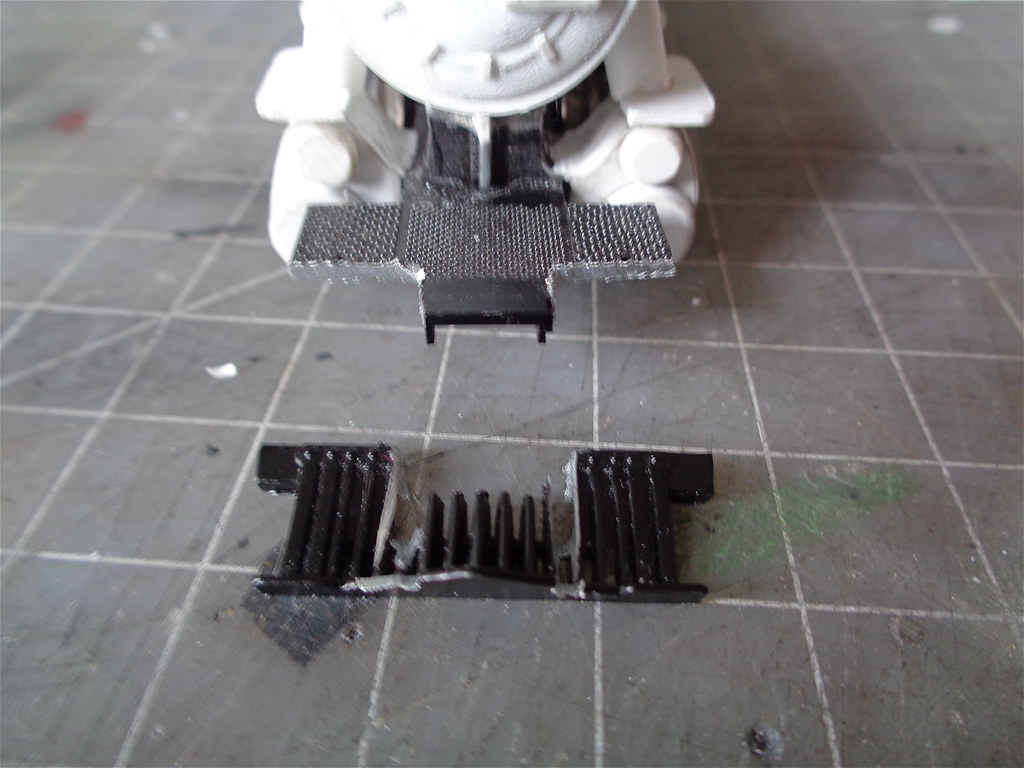

In the picture above you can see the base template for the frame work in the conversion. This was done be placing the cylinders face down on a piece of .010 styrene and tracing the cylinder. The top piston was traced using the smallest tube stock I had with right side of the circles being on the same line, then I drew a connecting line for the outside of cylinder and drew another line to slope the frame into the original steam chest. The piece is then cut using the lines as a guide. once one is made you can trace it to make the three others needed.

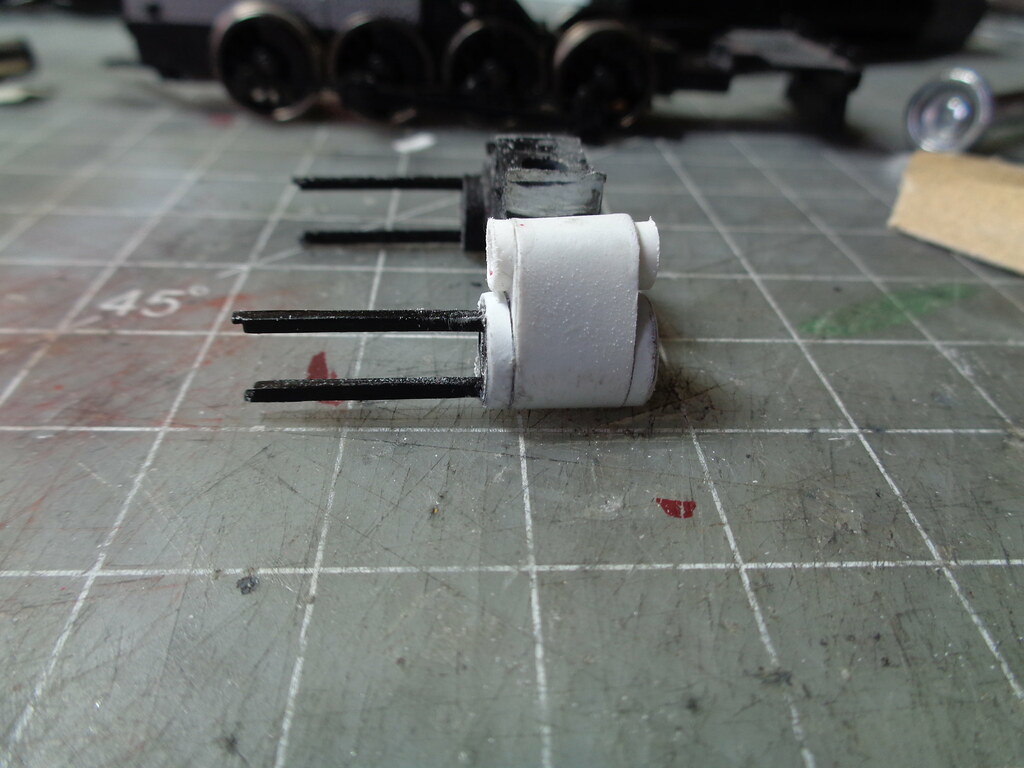

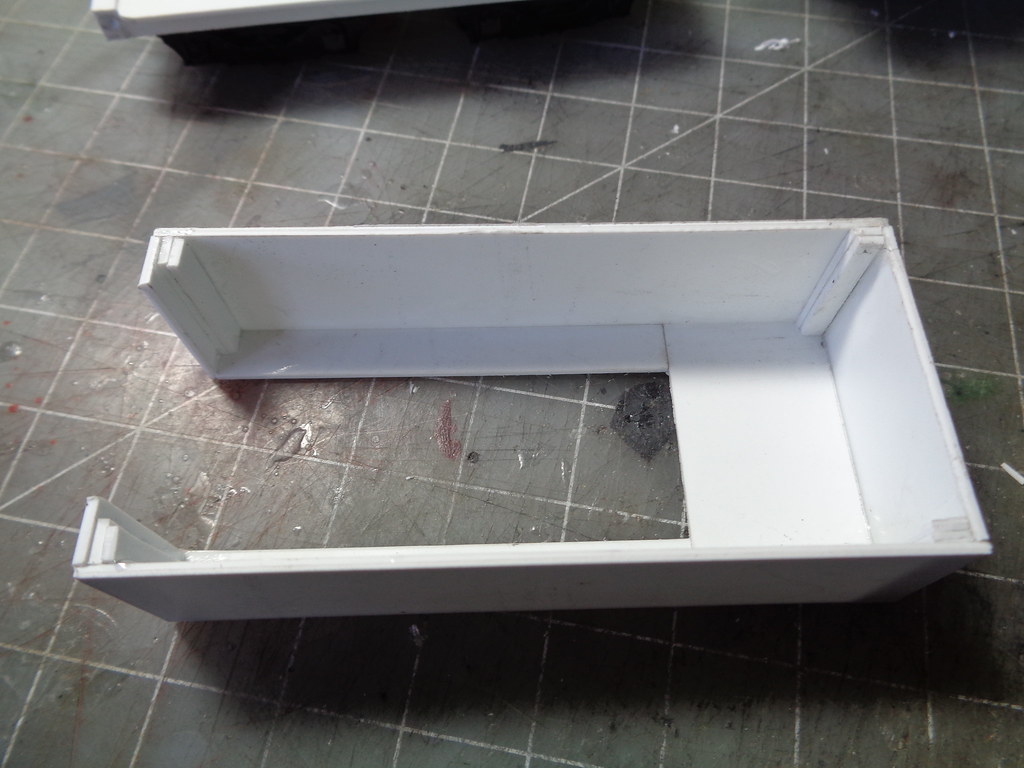

The pieces are then glued saddling the original piston, I eyeballed the angle they sit based on pictures.

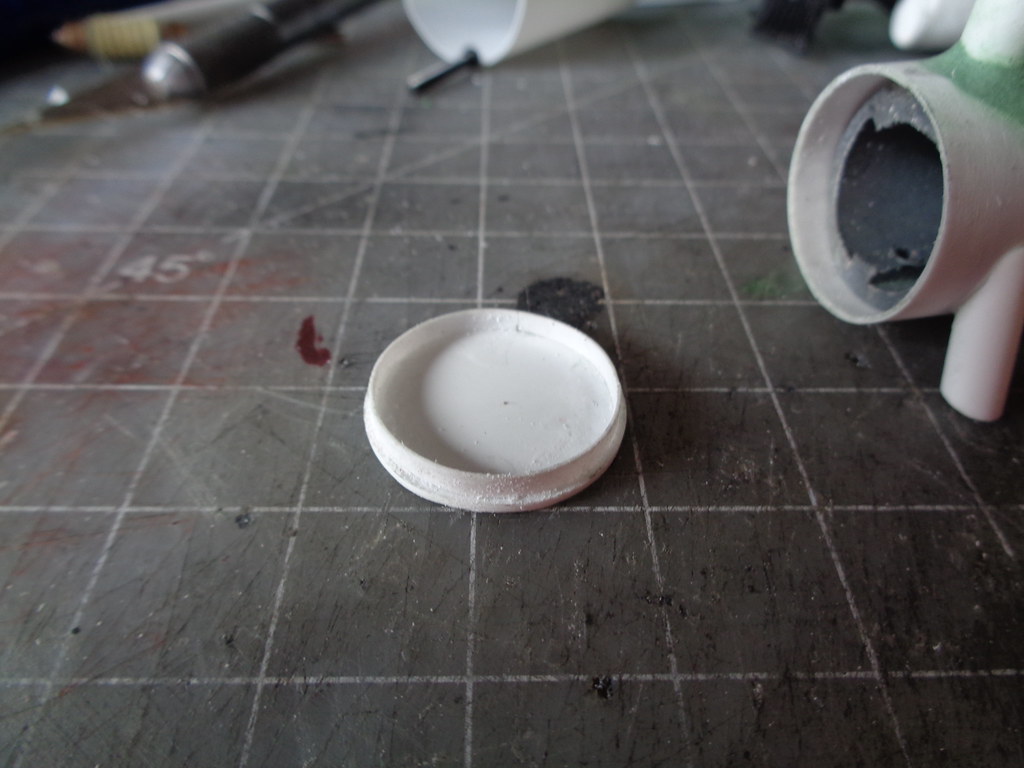

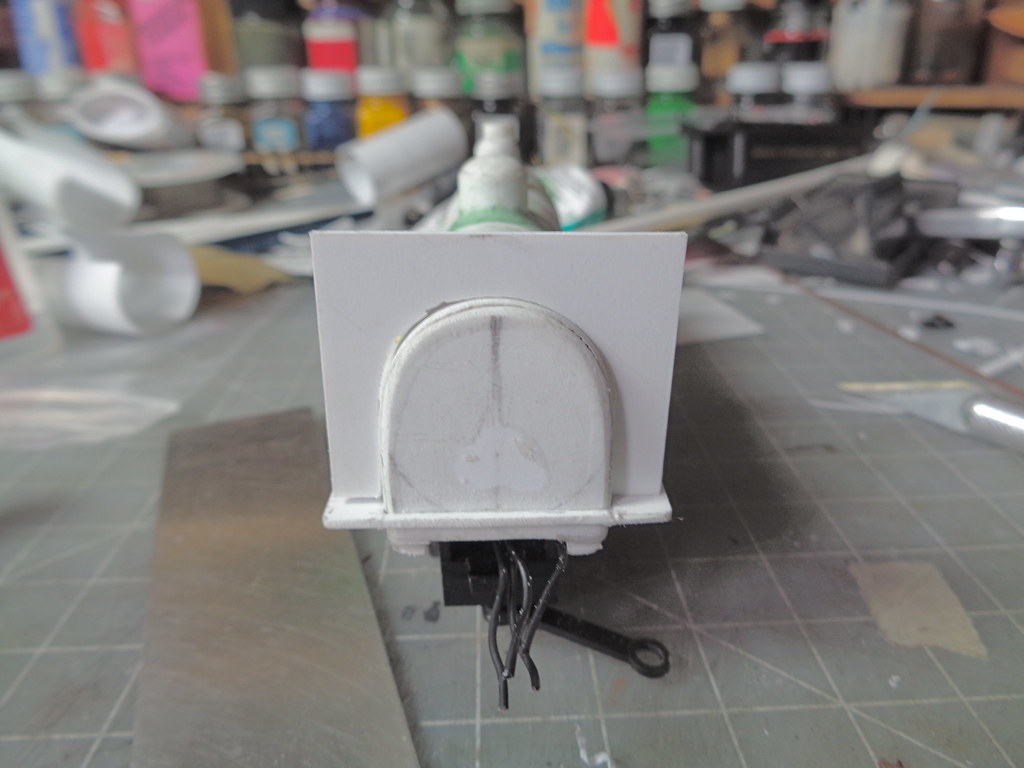

A piece of .010 is then glued to the frame starting close the the under side of the steam chest, wrapping all the way around to the steam chest again. The oricinal cylinder head was wrapped in .010 as well to bring it up to the same level as the new side wall and then I capped it with .010 and sanded the edges a little round to not have a hard edge. The stop piston was cut from tube stock to be the same width as the lower driving piston.

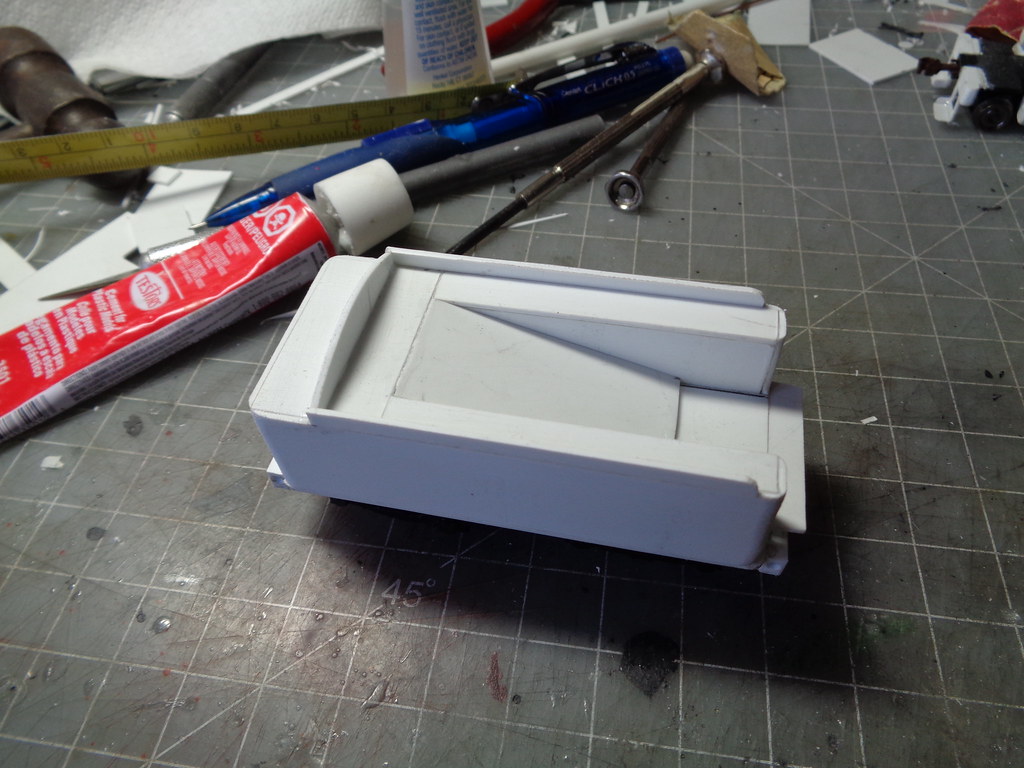

The top piston is then also capped with .010 and also sanded to not have a hard edge.

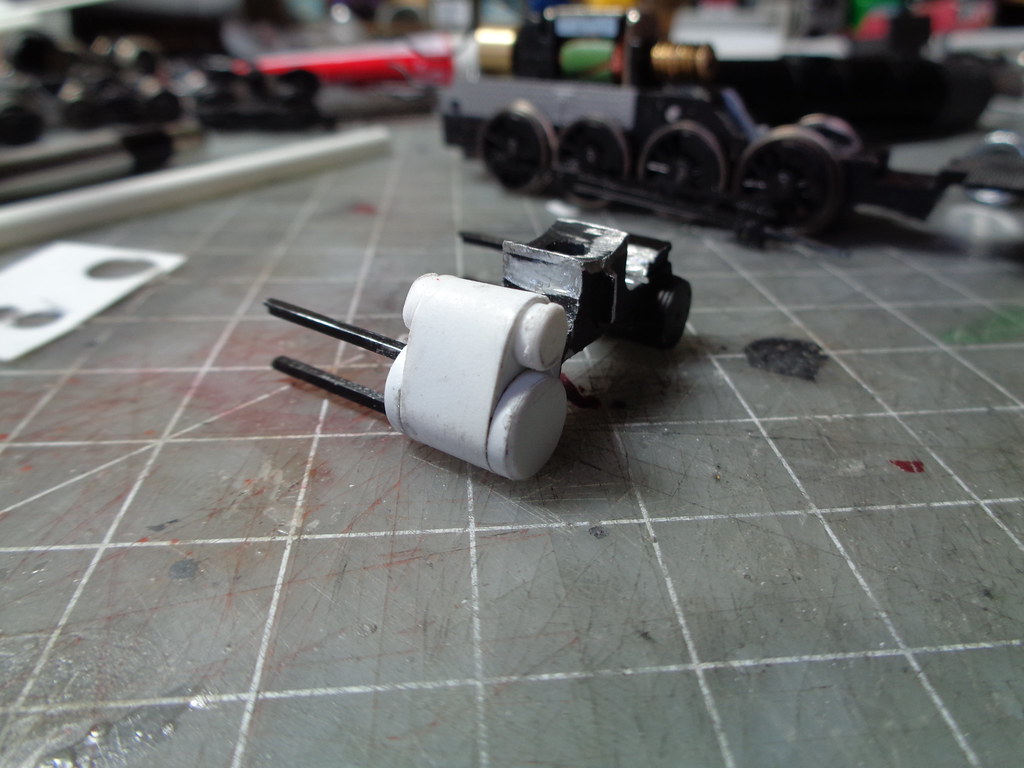

Once one side is done just repeat for the other.

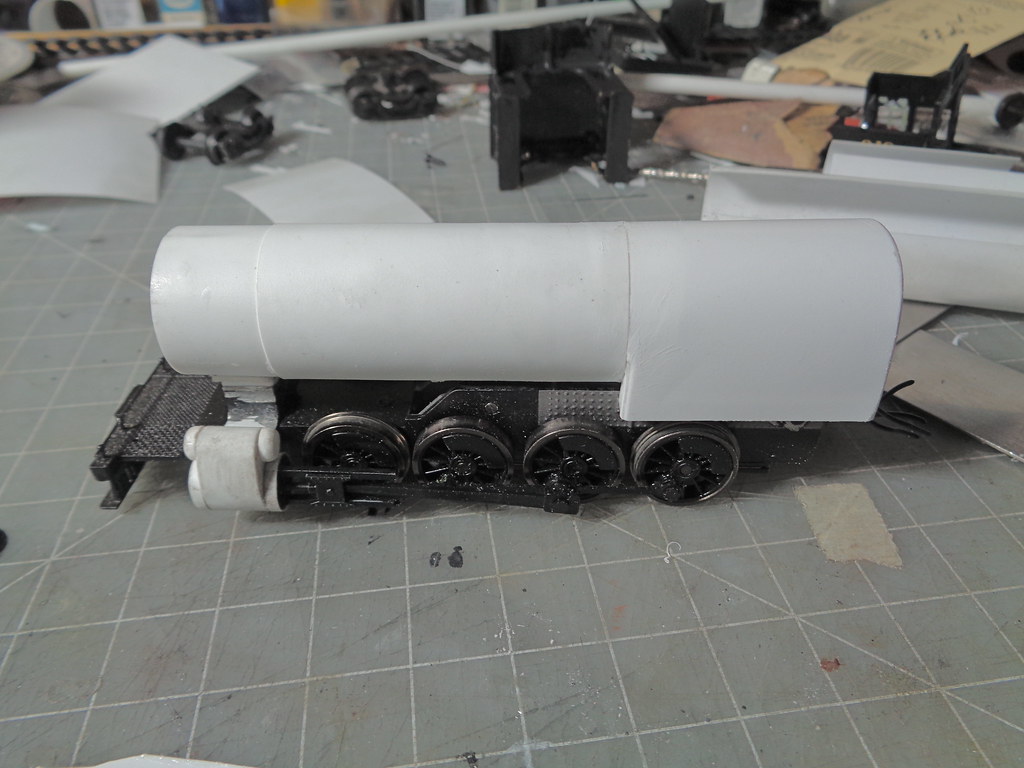

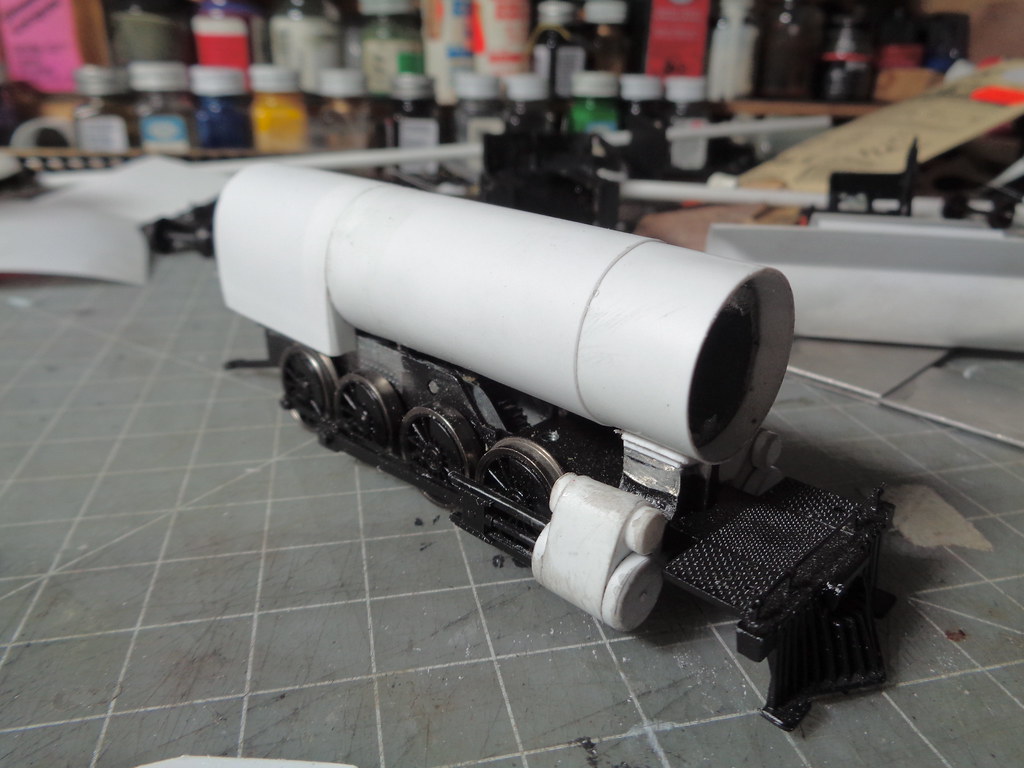

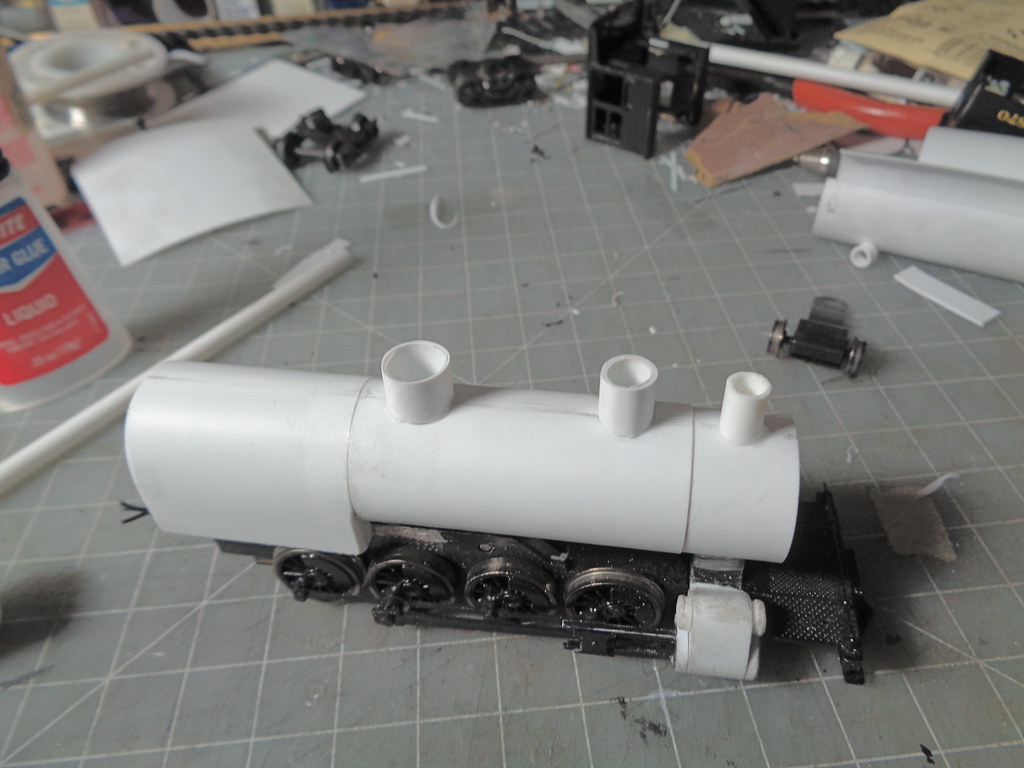

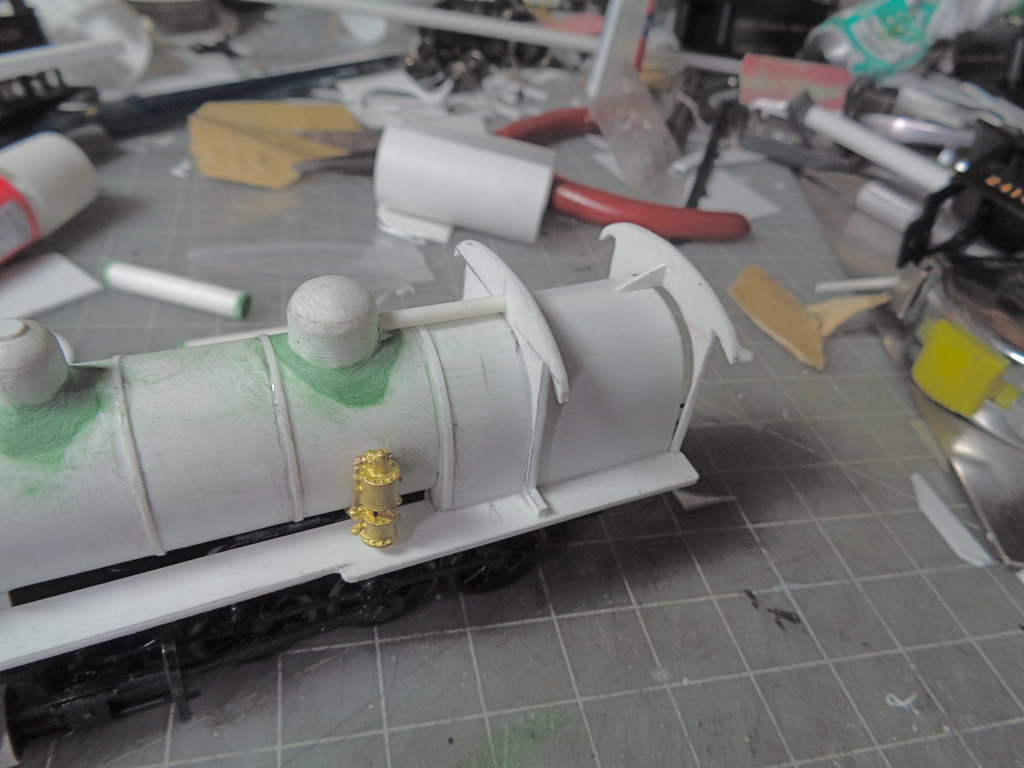

Now that the cylinders were set up attention shifted to the boiler. The plan is to use much of the weight of the original boiler, but resetting it in a way with a new tube making the boiler slightly bigger. To do this most of the detail was ground off. The smoke box was also cut shorter since Reading smoke boxes in general are quite short, I did keep the original mounting hole for the screw.

This is the new boiler tube taped up being 5 layers of .010, the top 3 will be used.

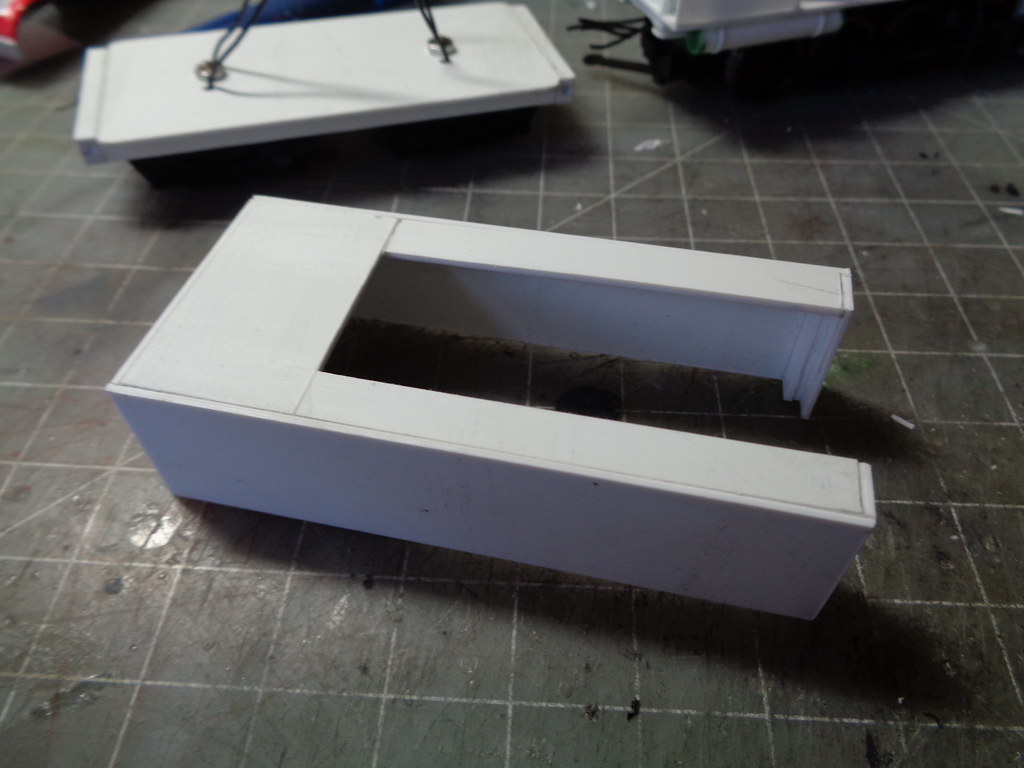

While setting the cured tube to what was left of the shell the steam chest extension was set in two layers of .040. One layer trimmed to the size of the chest and the top layer is set a little bigger for the boiler saddle.

This is where it sits at the moment.

A variety of Reading Company operations related documents, etc. that may be of use in your modeling efforts.

A variety of Reading Company operations related documents, etc. that may be of use in your modeling efforts. A variety of Reading Company operations paperwork, such as train orders, clearance forms, etc. that will help you operate your Reading layout in a prototypical manner.

A variety of Reading Company operations paperwork, such as train orders, clearance forms, etc. that will help you operate your Reading layout in a prototypical manner. Public Timetables, Employe Timetables, and Rulebooks that provide much useful operational information.

Public Timetables, Employe Timetables, and Rulebooks that provide much useful operational information. Signs, billboards, and other FREE goodies for your use. We ask only that you help spread the word about The Reading Modeler!

Signs, billboards, and other FREE goodies for your use. We ask only that you help spread the word about The Reading Modeler!