|

Welcome,

Guest

|

This section of The Interchange provides a space where members of the Reading Modeler community can showcase their Reading modeling efforts. If you've got a project that you'd like to share, start a new topic and "show and tell" the group how you did it!

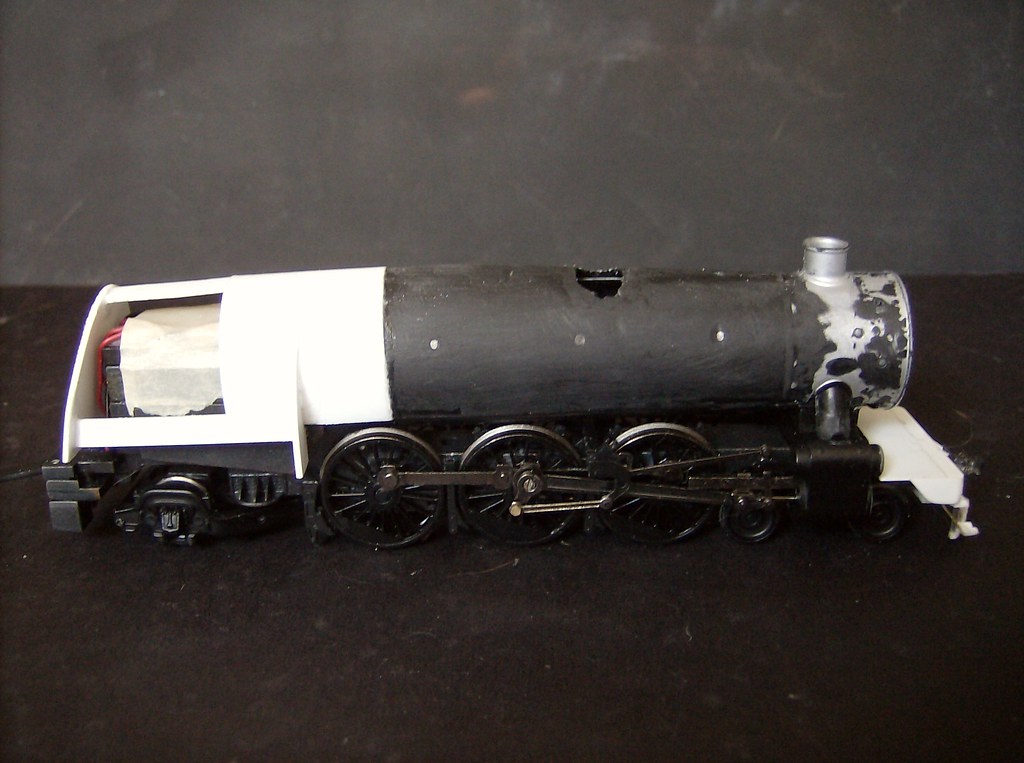

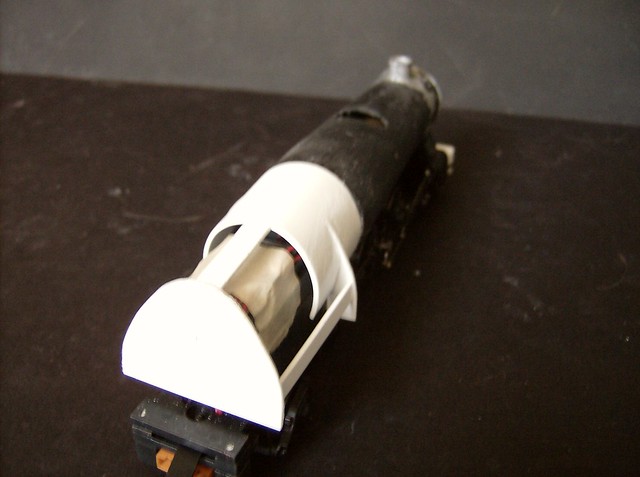

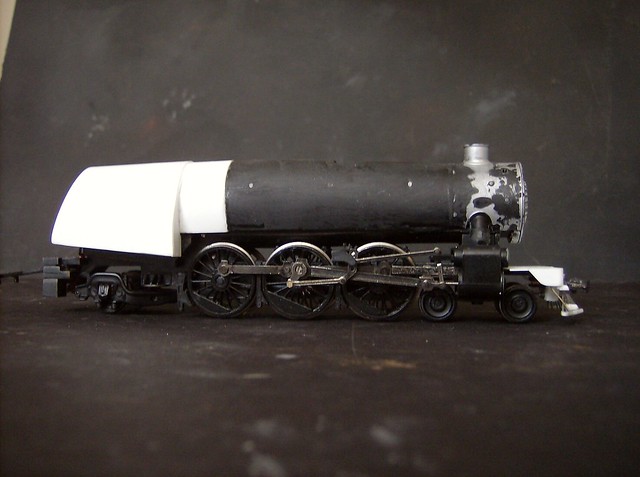

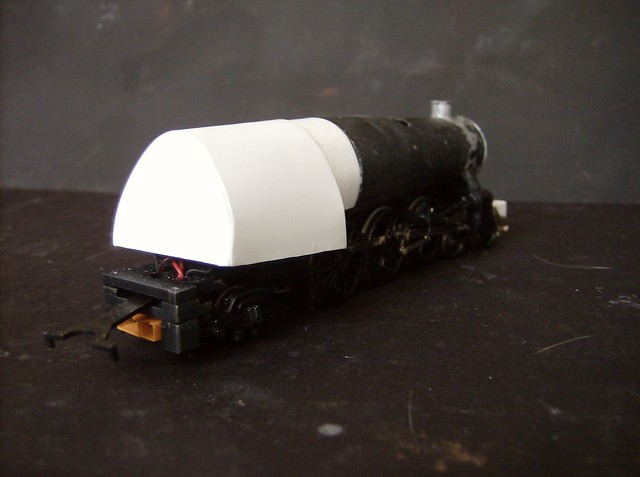

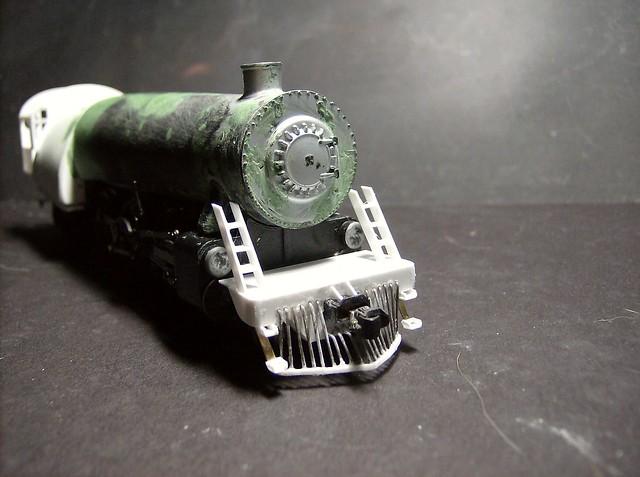

TOPIC: Semi-streamlined G-2sa

Semi-streamlined G-2sa 10 years 7 months ago #1896

|

Semi-streamlined G-2sa 10 years 6 months ago #2048

|

Semi-streamlined G-2sa 10 years 6 months ago #2069

|

Did You Know?

July, 1947

The new Lebanon Valley Branch bridge over the Schuylkill River at Reading, PA is completed, featuring the large "READING LINES" letting.

Downloads

Operations Information

A variety of Reading Company operations related documents, etc. that may be of use in your modeling efforts.

A variety of Reading Company operations related documents, etc. that may be of use in your modeling efforts.

Operations Paperwork

A variety of Reading Company operations paperwork, such as train orders, clearance forms, etc. that will help you operate your Reading layout in a prototypical manner.

A variety of Reading Company operations paperwork, such as train orders, clearance forms, etc. that will help you operate your Reading layout in a prototypical manner.

Timetables, Rulebooks, Etc.

Public Timetables, Employe Timetables, and Rulebooks that provide much useful operational information.

Public Timetables, Employe Timetables, and Rulebooks that provide much useful operational information.

Modeling Goodies

Signs, billboards, and other FREE goodies for your use. We ask only that you help spread the word about The Reading Modeler!

Signs, billboards, and other FREE goodies for your use. We ask only that you help spread the word about The Reading Modeler!

Rolling Stock Reference