The Reading's Continuous Welded Rail (CWR) Train

During the late 1960s, the railroads were faced with new technology and financially hard times. One of the new technologies was welded rail. The use of welded rail cuts maintenance costs that are usually associated with standard length rail, such as maintaining joints between sections of rail. It was also during this time that the Reading Company and New York Central went into an agreement to start a welded rail program.

Beginning in 1968, the Reading laid seventy seven miles of welded rail. This was also the same year as the infamous Pennsylvania Railroad/New York Central merger. As a result of this turn of events, the Reading chose to go it alone and start its own Continuous Welded Rail (CWR) program. In 1971, the Reading's mechanical forces went to the drawing board and designed a welded rail train for the railroad's use, turning to Lewis Rail Services and friendly partner the Western Maryland Railway for technical advice. The technical insight gained from these two parties greatly influenced the Reading’s own designs. The Reading welded standard length sections of rail into 1440 foot lengths for mainline use. Ever frugal, the Reading then removed the old rail and sent it back to the shop, where the ends were cropped and welded together for use on lighter traffic freight-only lines.

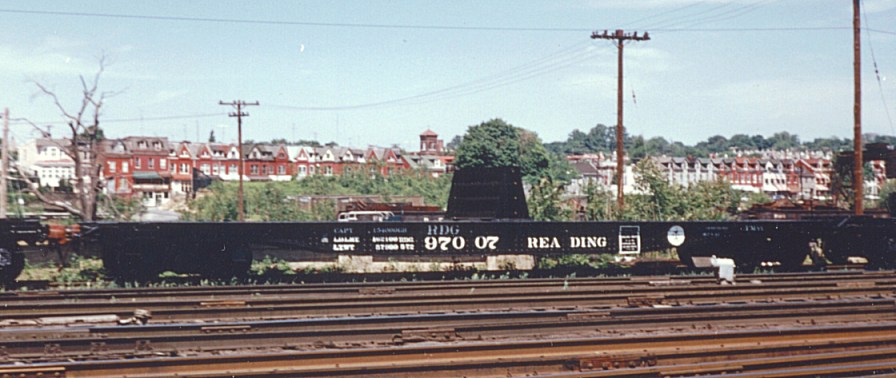

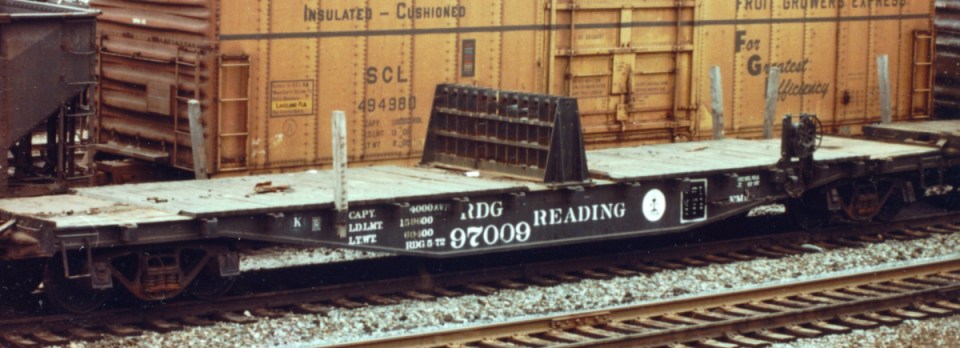

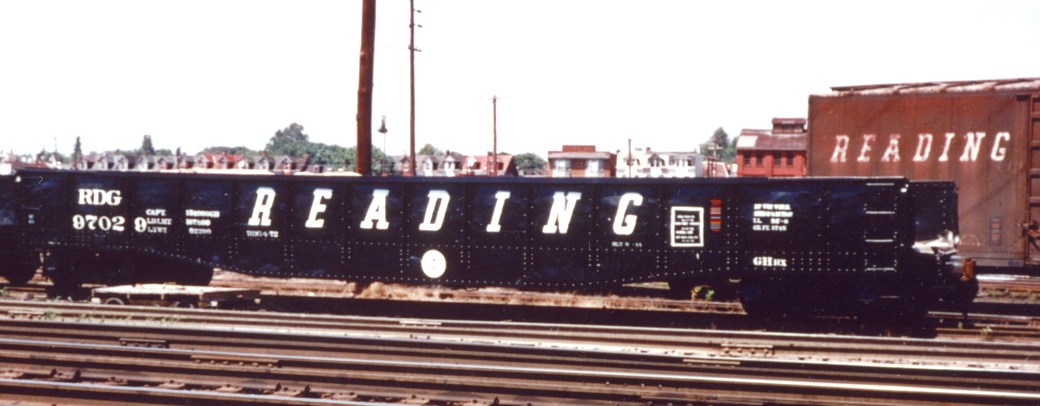

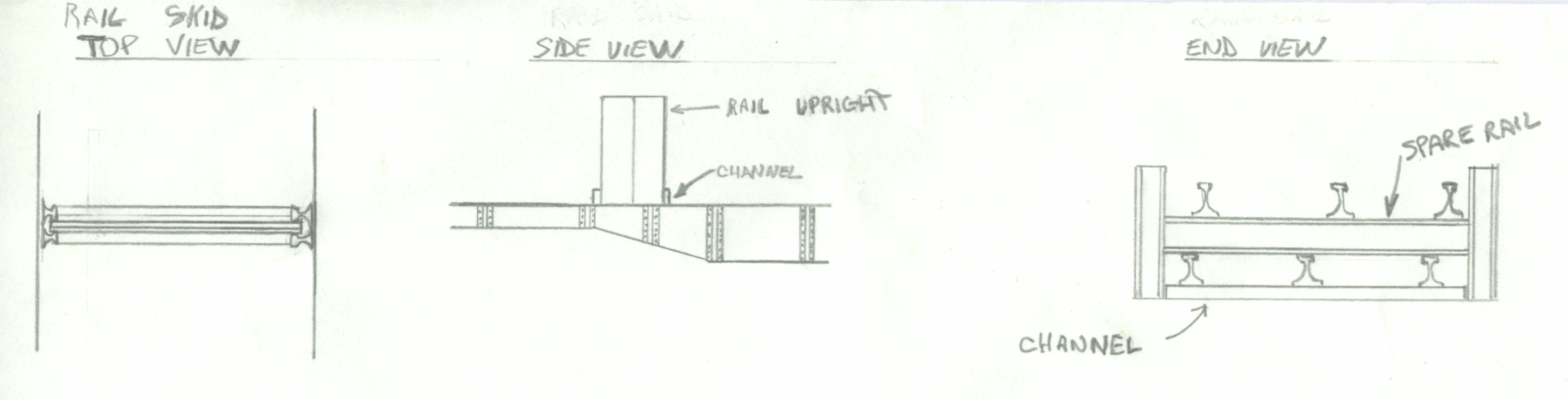

In February 1972, the Car Shops at Reading, PA converted the cars needed for CWR Train service. Thirty-one cars were rebuilt to CWR Train specifications. When painted in May and June of 1972, the CWR cars were given the 97000-97030 number series. Most cars came from the FMe class of flatcars. All but one of these cars were equipped with roller stands. One oddball flatcar was fitted with a rail tiedown rack. A few flatcars from the FMn class were also fitted with roller stands. Three gondolas were also rebuilt for this service. Two were used as end protection cars should a welded rail break loose and slide freely during transit. The last gondola was used as a runoff car to guide the welded rail off the roller stands down toward the track where it could be installed. In 1975, the Reading was faced with a shortage of cars for CWR service. So, in April of that year twelve more cars were added and given the 97031-97042 number series. These later cars were fitted with rail skids rather than roller stands as with the original batch of cars. These rail skids were cheaper and faster to build. Two rail skids were required per car; One was attached 1/3 of the way in from the “A" end of the car. The second rail skid was attached 1/3 of the way in from the "B" end of the car.

A single rail skid was built with two rails 2’-3” long standing upright. These two rails were placed side by side and butt-welded to each other and to the edge of the cars floor. One rail upright was welded to the left hand side of the car. Another rail upright was welded to the right hand side of the car's floor. After the two uprights were installed, a piece of steel channel was welded upside down between the two uprights. When this step was completed, the installers' attention was turned to the other side of the car. It is here that the other rail upright was assembled and put in place (refer to the drawing below for clarification).

A piece of old spare rail was cut off and placed between the two uprights to form the rail skid. This rail was laid down between the two upright rails that were butt-welded together to the form a channel. The uprights held the skid rail in place and kept it from moving. When loading the cars equipped with rail skids, a layer of welded rail was placed on top of the upside down channel. Then the short piece of skid rail was fitted into place between the two uprights. Now a second layer of welded rail was laid on top of the skid rail. These rail skids acted as makeshift roller stands. The rail would slide over the top of the skid rail that was inserted into the rail skid stand.

At some time in its career, the runoff car was modified, either in the late Reading or early Conrail years. When rebuilt, a larger “I” beam for the rail threader and a spacer between the “I” beam and the car floor were added. Also, the “U” bolts holding the rail threader in position were replaced when rebuilt. New steel straps were welded to it and the car's floor.

After the transition to Conrail ownership on April 1, 1976, all welded rail train cars from all the former railroads that Conrail took over were assigned to the Lucknow Plant near Harrisburg, PA. The Reading's former CWR Train cars lasted into the early 1980s before being retired from that role. Some of the cars were later reassigned to Maintenance of Way jobs all over the Conrail system. Some even lasted into the year 2000. One such car, #97035, is presently in service for the Reading and Northern RR. Car #97037 was seen in MOW service at Chicago in 2003. Car # 97038 is presently in service at South Plainfield, NJ.

The following series of photos shows the various types of cars that made up the Reading's Continuous Welded Rail Train as described above. All photos by C. T. Bossler, collection of John Caples. A spreadsheet containing a roster of the CWR Train cars can be found here.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ACKNOWLEDGEMENTS: The author wishes to thank Craig T. Bossler. Were it not for his generosity in making his photos available, this article would not have been possible. Also, a big thank you is due to Bob Danner for spending many long hours assisting with research on this piece of Reading history, often into the wee hours of the morning!

Did You Know?

Downloads

A variety of Reading Company operations related documents, etc. that may be of use in your modeling efforts.

A variety of Reading Company operations related documents, etc. that may be of use in your modeling efforts.

A variety of Reading Company operations paperwork, such as train orders, clearance forms, etc. that will help you operate your Reading layout in a prototypical manner.

A variety of Reading Company operations paperwork, such as train orders, clearance forms, etc. that will help you operate your Reading layout in a prototypical manner.

Public Timetables, Employe Timetables, and Rulebooks that provide much useful operational information.

Public Timetables, Employe Timetables, and Rulebooks that provide much useful operational information.

Signs, billboards, and other FREE goodies for your use. We ask only that you help spread the word about The Reading Modeler!

Signs, billboards, and other FREE goodies for your use. We ask only that you help spread the word about The Reading Modeler!