I got a lot of this done this week, taking advantage of the cool weather. I had this feeling the boiler was too small and had to prove to myself that was I thought I was doing was right and pushed it until I got to that point and then decided to work on it more.

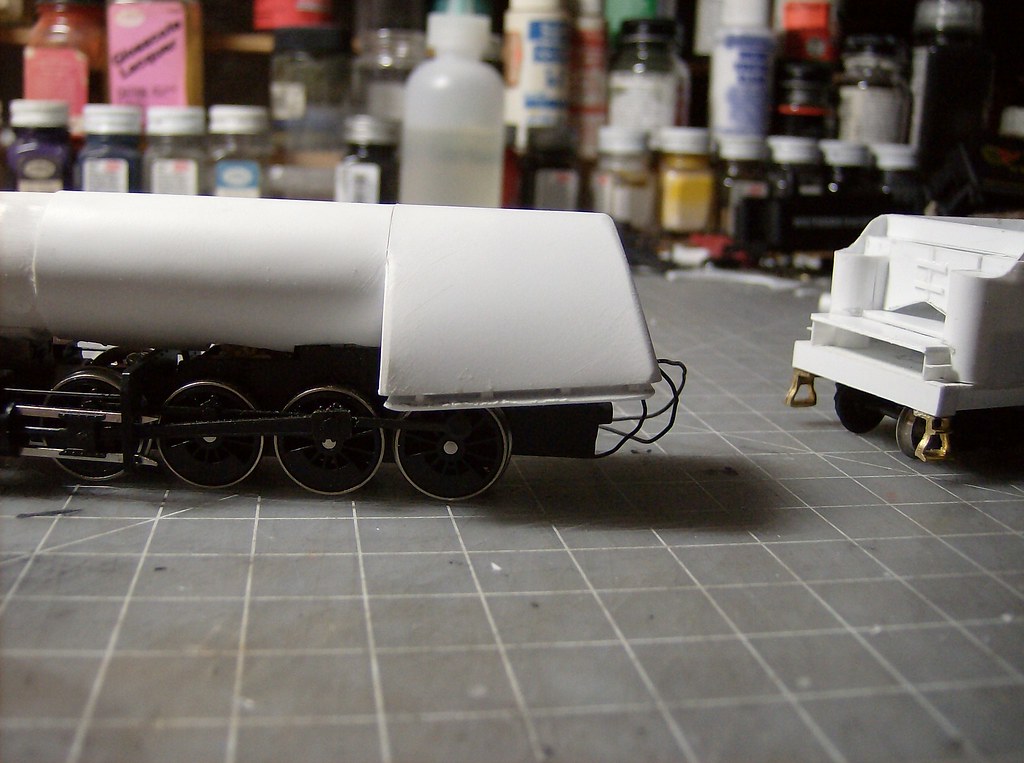

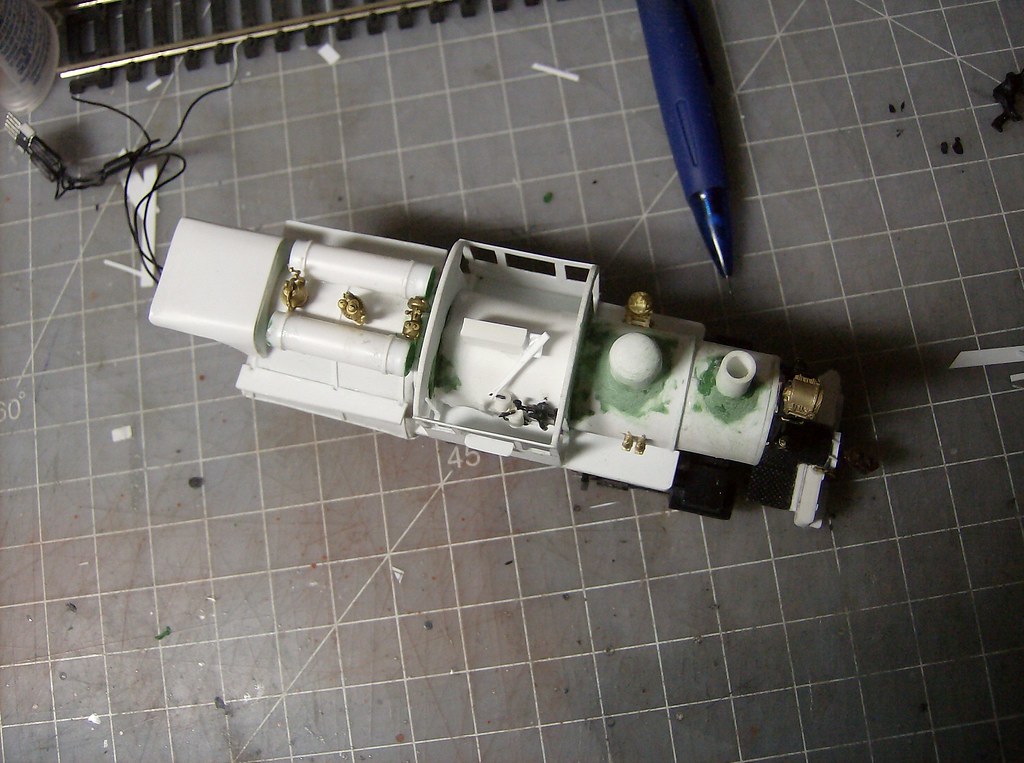

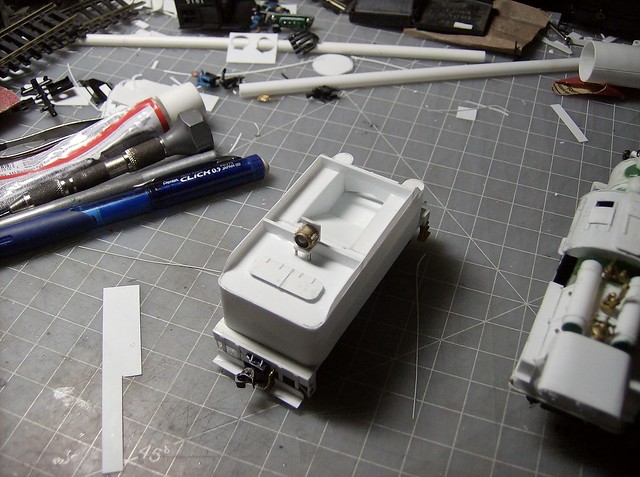

Work resumed on the tender making the coal bunker.

Then the sides when up being .010 and 1/8" high. The bunker walls followed.

Using the bottom of the firebox as a guide the deck was placed.

Here is a height comparison of the original to the built to an IHC more modern tender. As you can see I was going for in between.

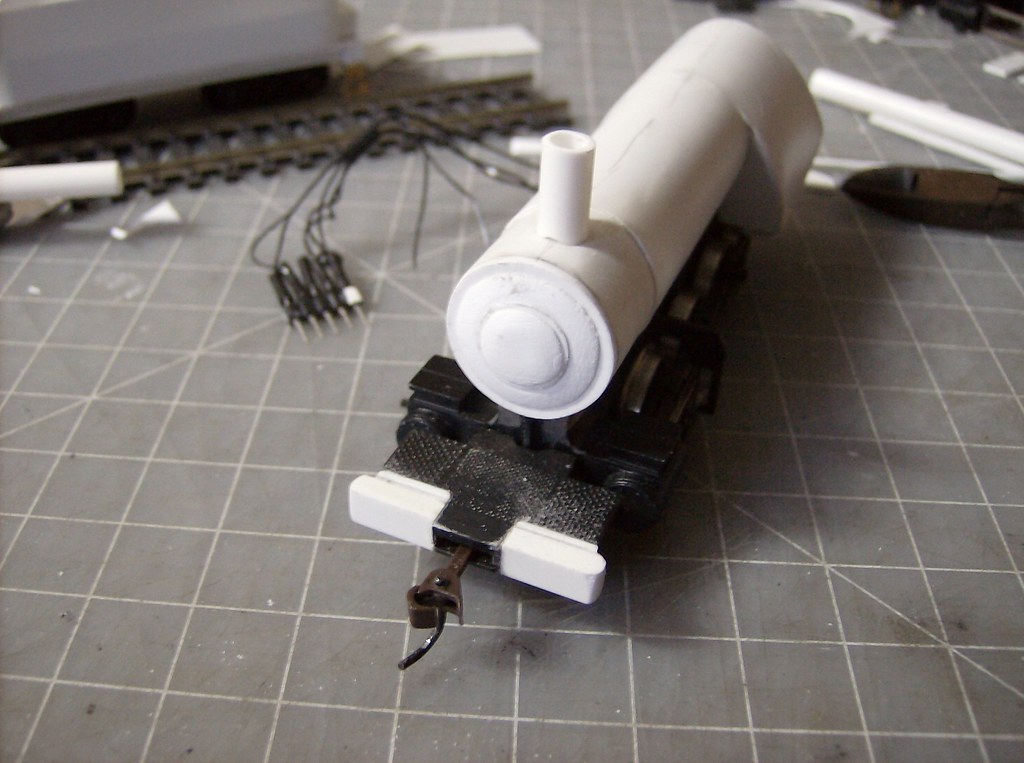

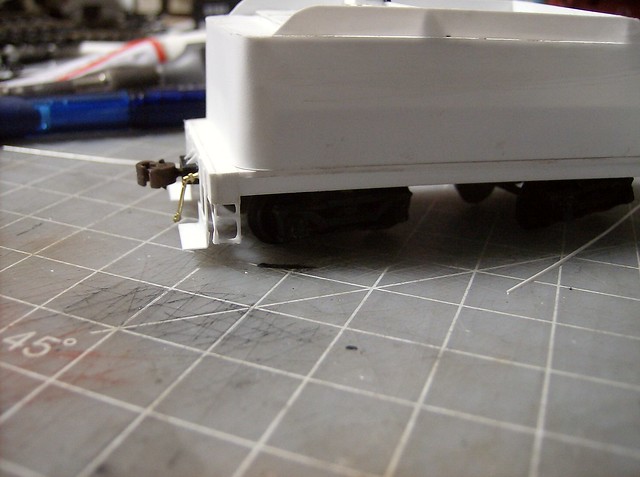

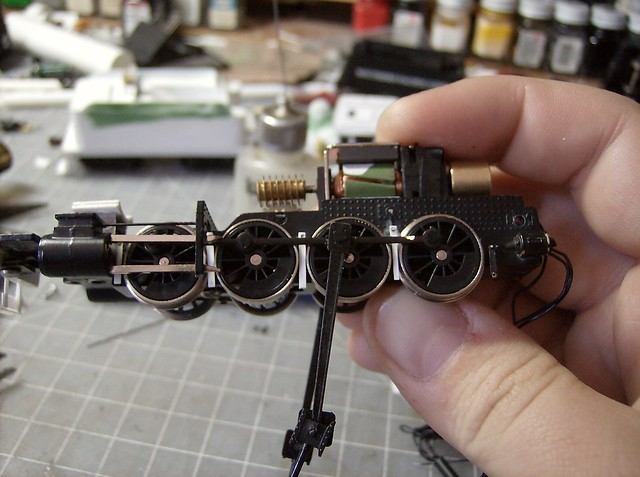

With a bulk of the tender done focus returned to the engine starting with placing the ash pans. They are made from .040 with .040 spacers.

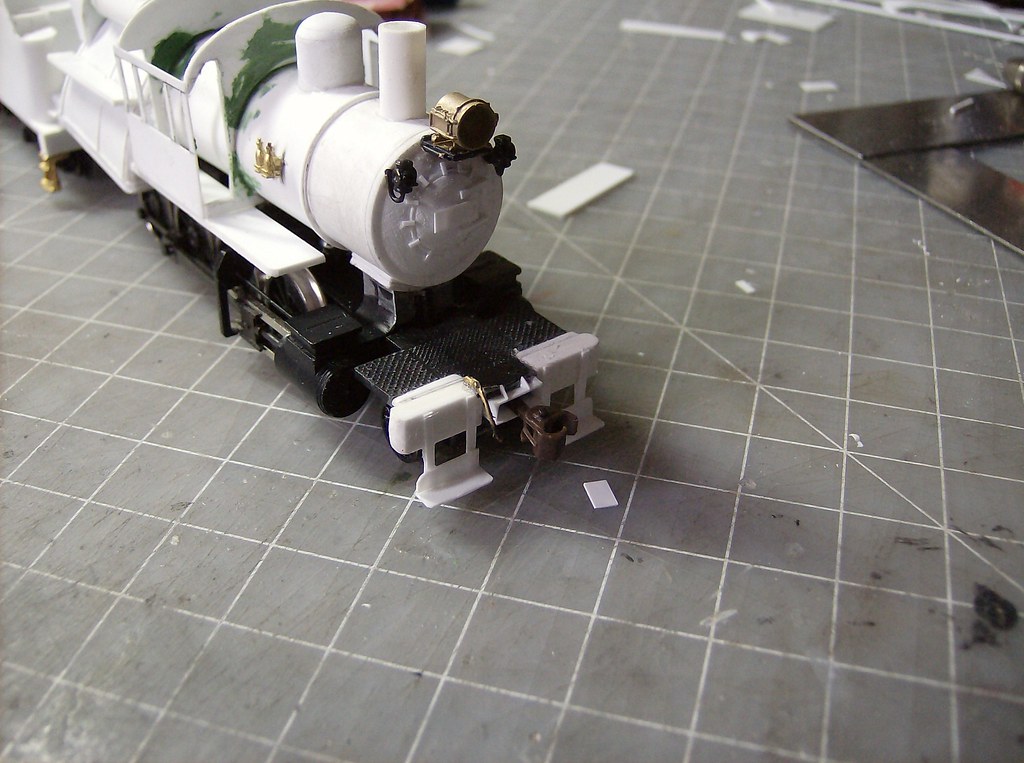

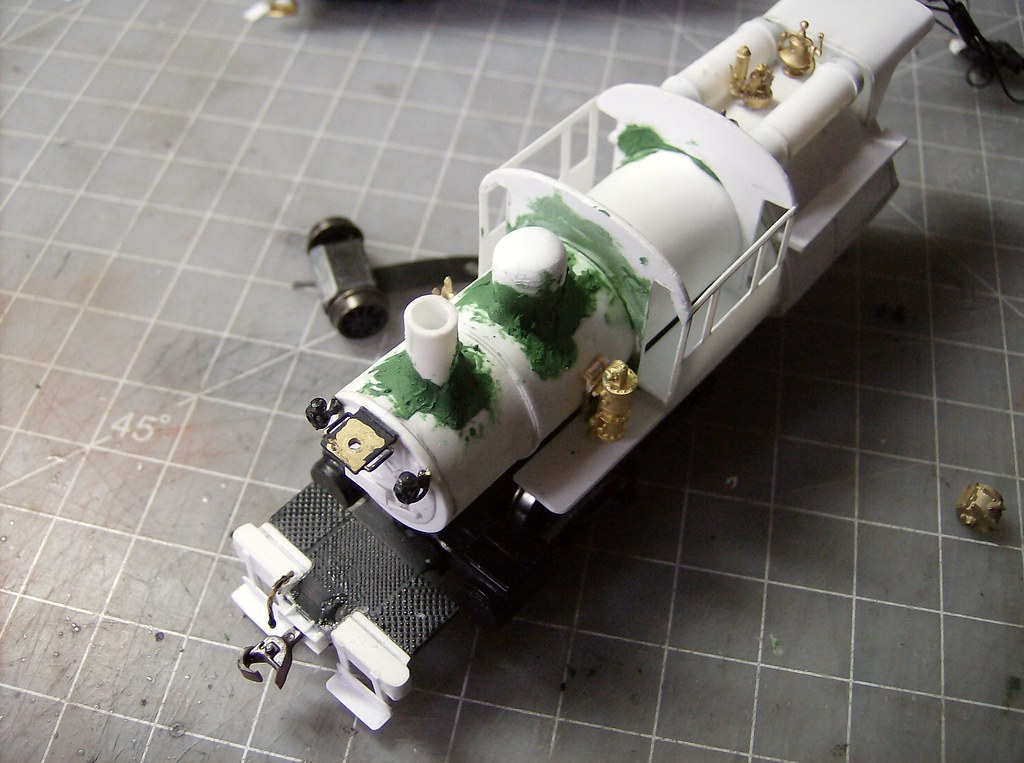

A piece of styrene was cut as a guesstimate which can always be sanded later. Then the smokebox base was placed in the .040, .010, .040 sandwich I have used before. The hinges and latches are .010 pieces, the headlight and number board were also place at this point. I chose the rectangular number board which the engines got late in life just before retirement. Through most of their career they would have had a circle number board.

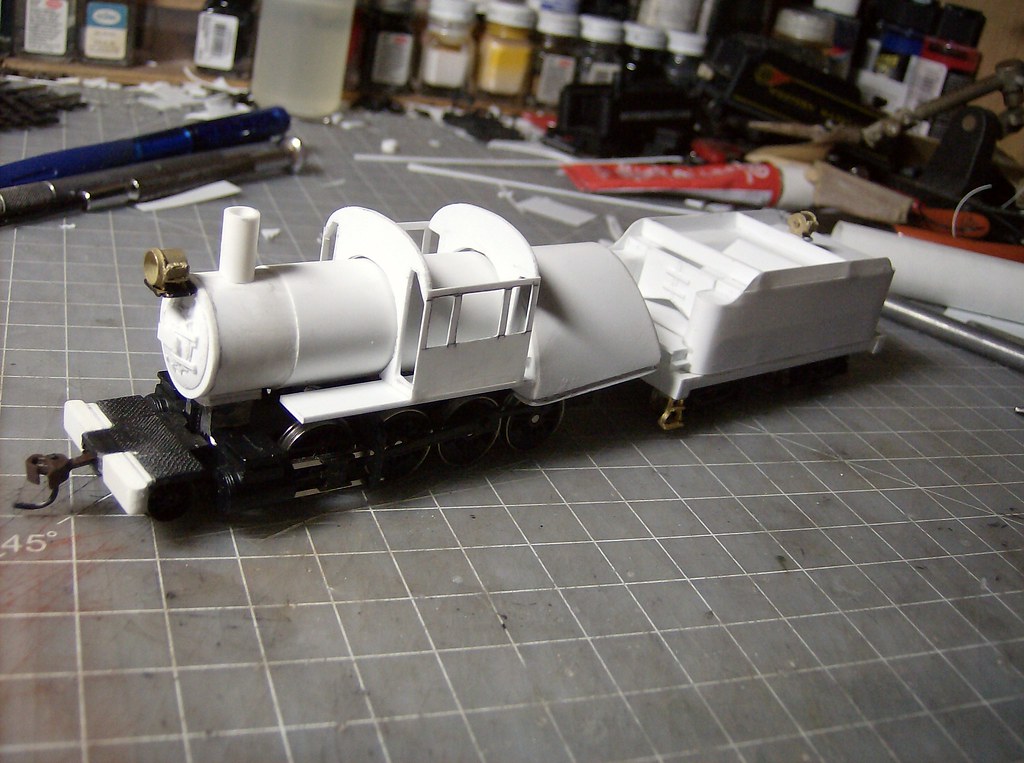

Then the running boards were installed glued to the front of the firebox.

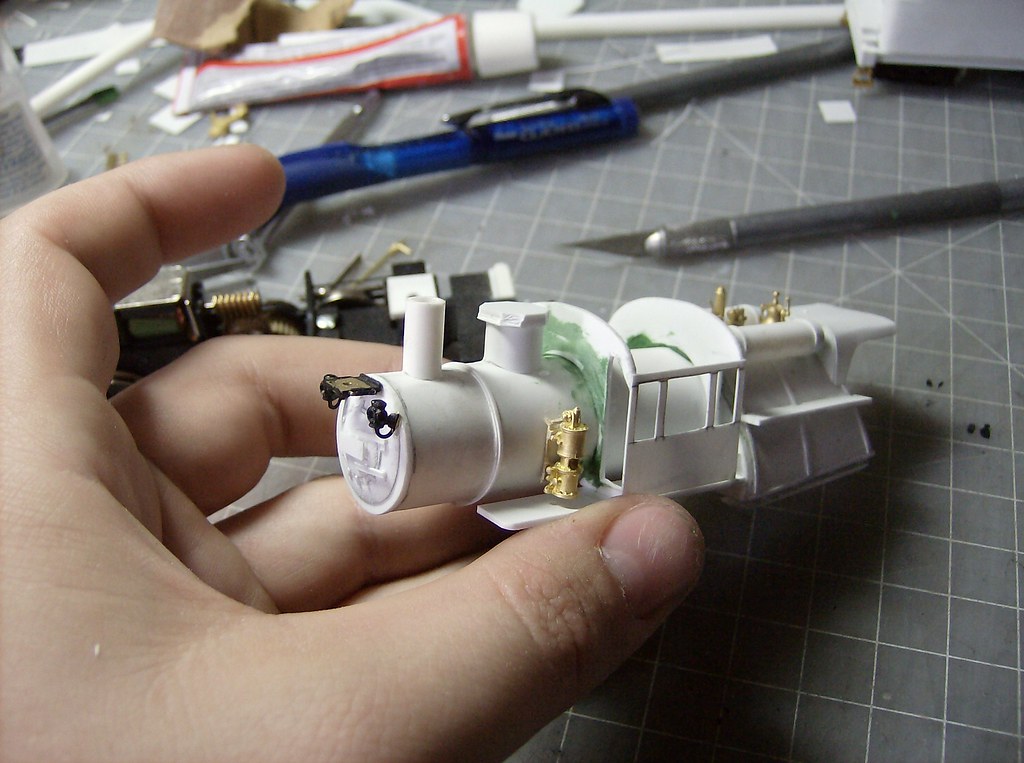

I wanted to revise my cab design a little as some of the full .010 cabs have drooped a little after being finished. This is normally fixable but I'd rather not have to. I went with .040 front and back walls with the rear section being glued to the running board first. Then the cab sides, still .010 were glued to the rear wall, and the front wall followed being glued to the side then the floor. This gut down on measuring and having to place the front and back perfectly before the sides went in. I also meant to do the window frames on the cab side before they were installed but forgot. Not a huge problem its just easier to do it that way. Putty was used later to fill any open seam around the boiler.

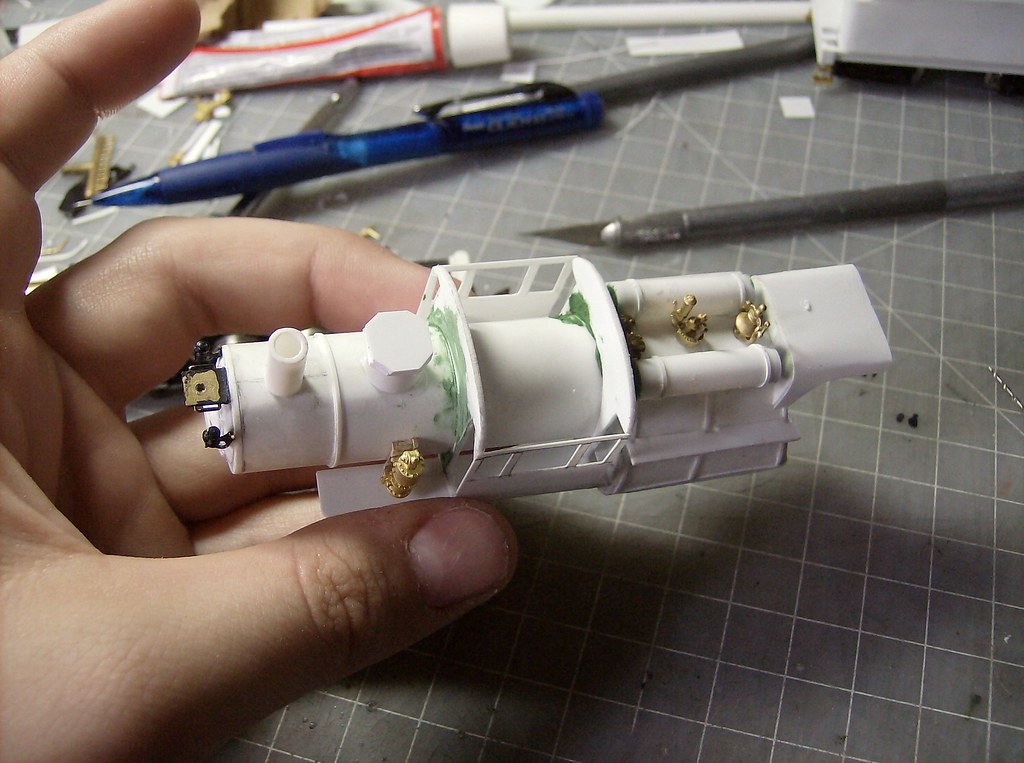

Next was the rear shade, starting with the .040 base. Then a piece of .010 was wrapped around the frame. To keep the shape at the end, a piece of .040 is glued to the rear under side.

The boiler bands and air tanks were next to go on.

This was the point it was looking right to me.

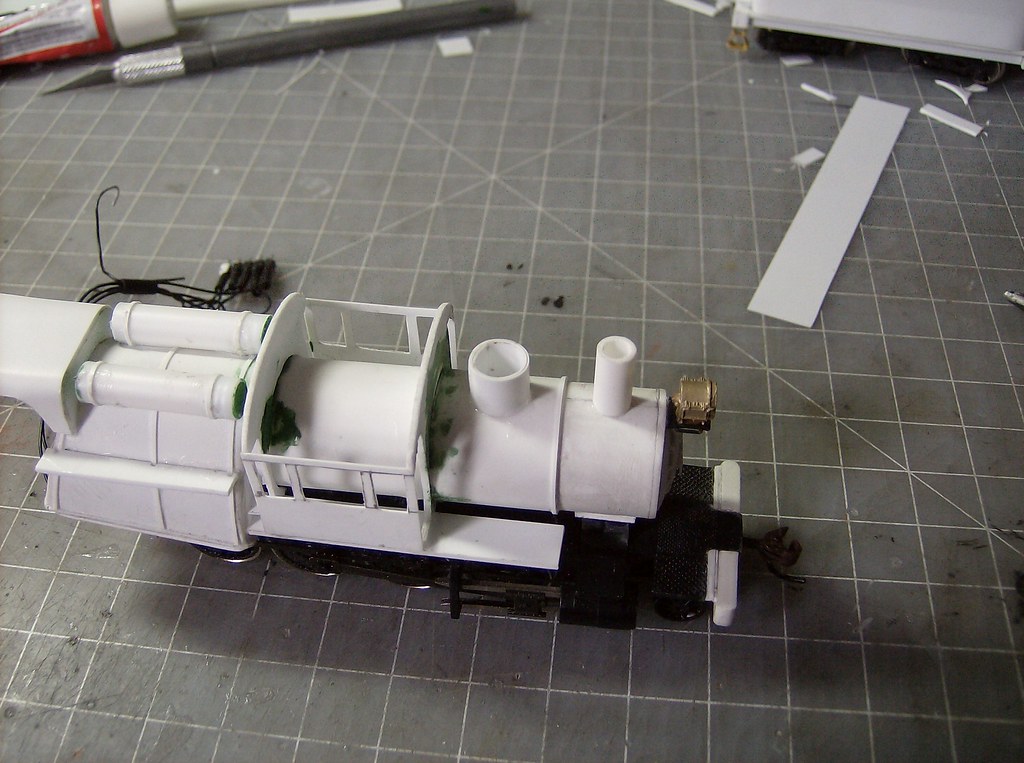

The sand dome is placed in the center of the short boiler section between the cab and smokebox. The dome started as .010 wrapped around several times and glued together with the outer seam then sanded flush. It was then capped with 2 layers of .040 and sanded round to finished the dome shape. Other parts appeared as I was waiting for things to dry.

Also while things were drying I got some finishing done on the pilot, first extending the coupler pocket and then making the footboards.

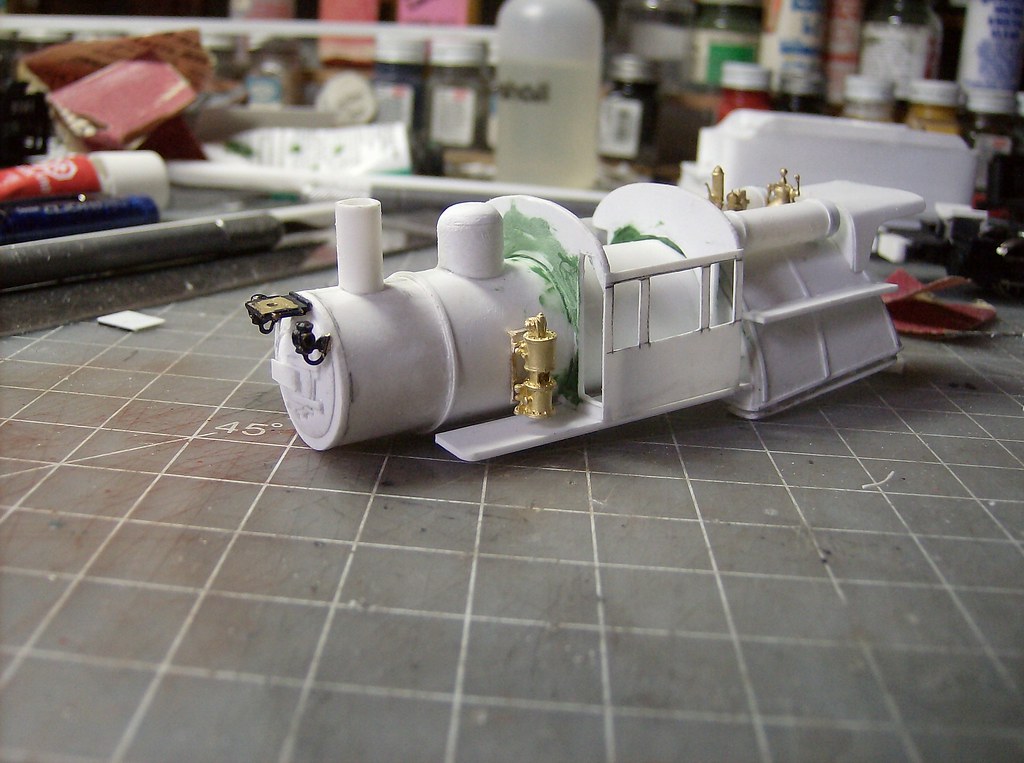

The stack and dome were then puttied and left to dry. After drying the putty was sanded.

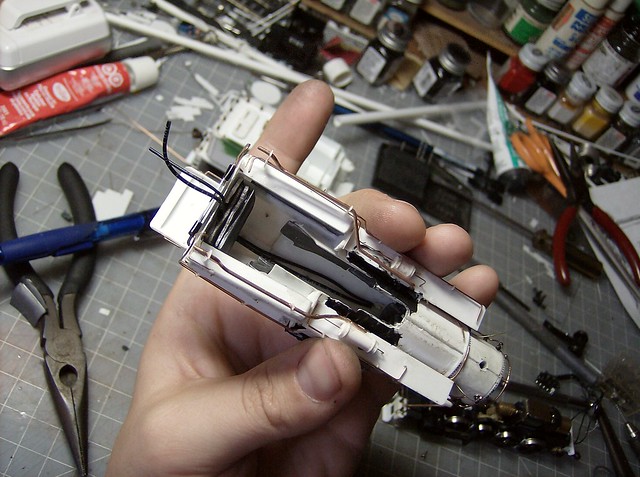

I wanted to do something for a cab interior on this one. Nothing too complex just something to give the idea of controls. The block in the center is quick steam dome, if you can manage to see it with the roof on. The injector lifter is a reused bachmann spectrum 2-8-0 piece.

I even dismembered and reassembled an old proto 2000 diesel figure for a cab figure. This one will be the first to have an engineer.

The roof is .010 fitted for the base dimensions then the center line is found and the vent holes are cut. Then the vents are placed on the glued down roof.

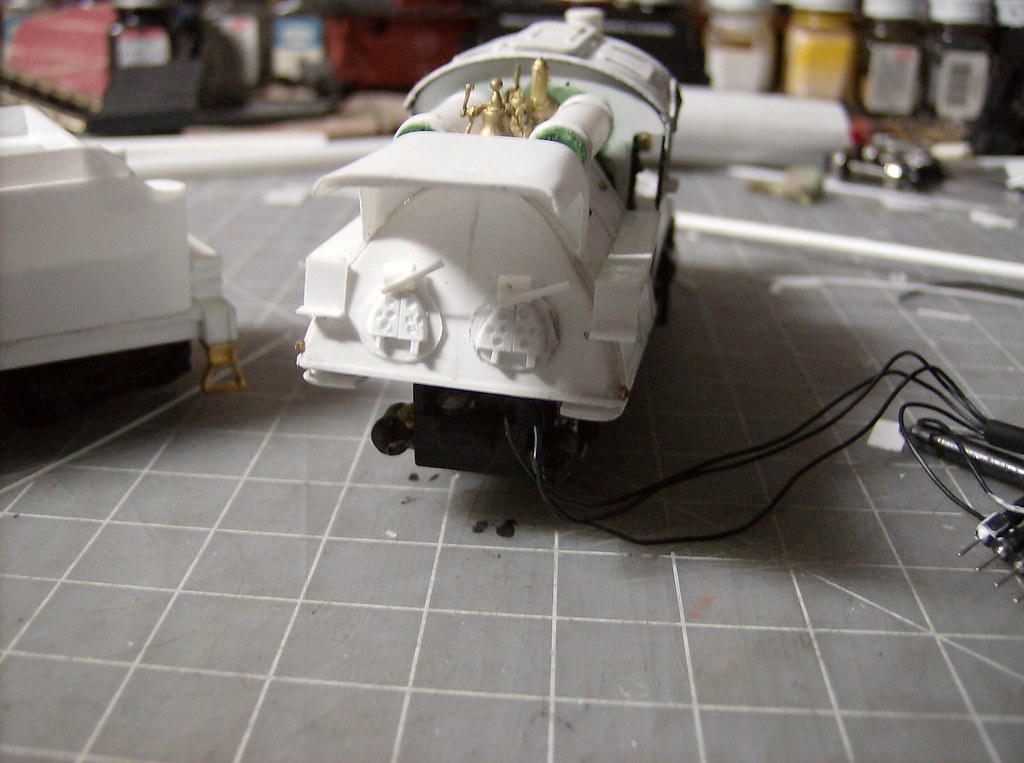

Heres where it sits now. There is still a bunch of little things to do before final detailing.

A variety of Reading Company operations related documents, etc. that may be of use in your modeling efforts.

A variety of Reading Company operations related documents, etc. that may be of use in your modeling efforts. A variety of Reading Company operations paperwork, such as train orders, clearance forms, etc. that will help you operate your Reading layout in a prototypical manner.

A variety of Reading Company operations paperwork, such as train orders, clearance forms, etc. that will help you operate your Reading layout in a prototypical manner. Public Timetables, Employe Timetables, and Rulebooks that provide much useful operational information.

Public Timetables, Employe Timetables, and Rulebooks that provide much useful operational information. Signs, billboards, and other FREE goodies for your use. We ask only that you help spread the word about The Reading Modeler!

Signs, billboards, and other FREE goodies for your use. We ask only that you help spread the word about The Reading Modeler!