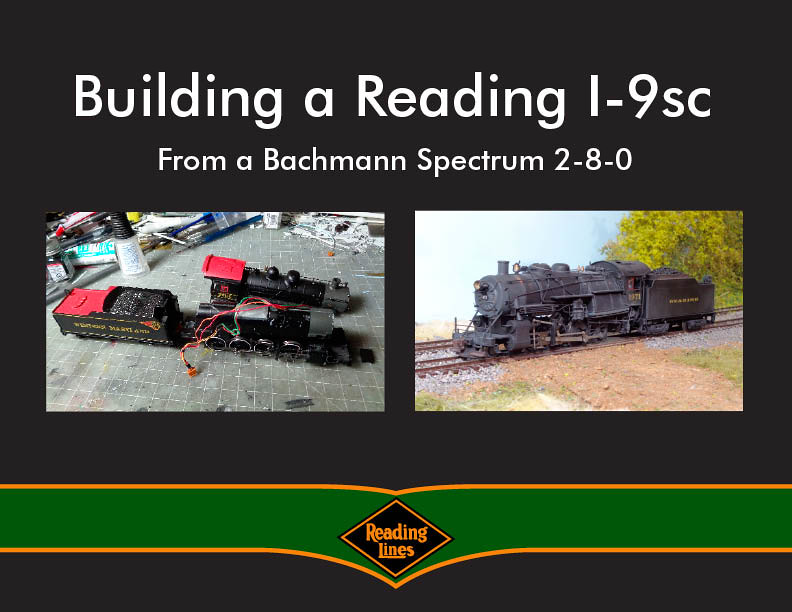

This is the clinic I did at the 2017 Reading Modeler's meet on building an I-9sc 2-8-0 from a Bachmann Spectrum 2-8-0. These were the group of 2-8-0s that were rebuilt using I-10 larger drivers from the I-10s that were themselves built into T-1s. The original idea was to just film the clinic but that didn't work out, so I doing the written version.

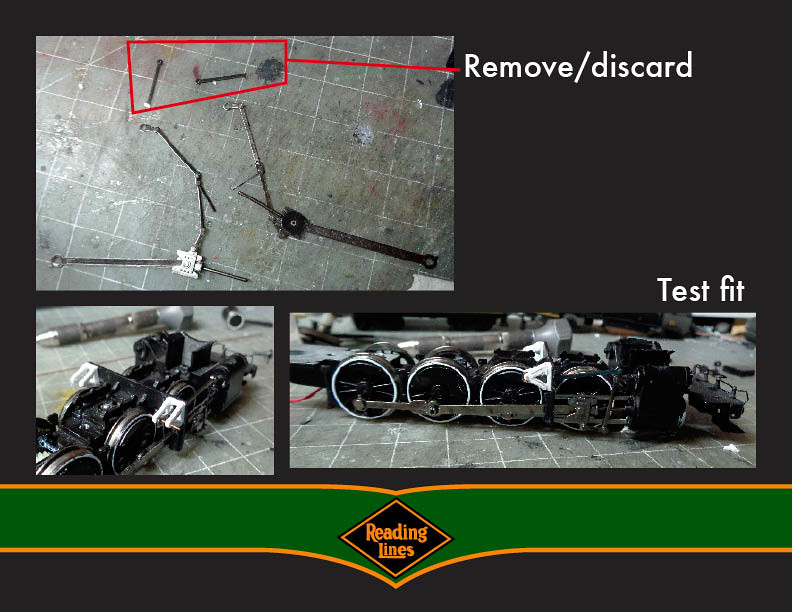

Step one for me is always getting the running gear looking right and running right. In the images you can see the spectrum engine torn down to the frame with running gear from an old Bachmann I-10 that will be used to rebuild the running gear. Then the rods are taken off the spectrum frame to begin work on the valve gear conversion.

The baker valve gear gets completely removed with the spectrum eccentric crank, rod and link not being used for this project. The old hanger is also cut off with the cleaned off yoke being seen sitting back on the frame ready to get the new hanger for the walsherts valve gear.

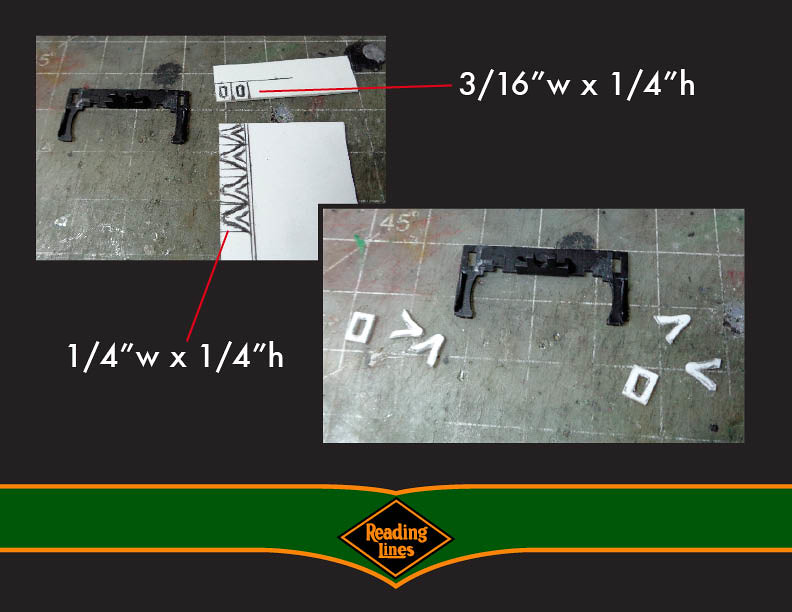

The base measurements for the new hanger come from measuring where the link sat for the baker, not having to reinvent the wheel. Drawing out the 1/4" x 1/4" squares the V shapes are drawn in with the points being centered in the space. The .040 styrene shapes are then cut out.

Everything is then assembled on the yoke.

The new hanger is then drilled for the .020 wire that will hold the walsherts link in place.

To reset the spectrum rods, the baker adjustment bar needs to be removed. The rods can then be set with the loop at the end of the small rod that was just trimmed having the .020 wire set through it. I tend to give it a quick test roll at this point as well just to make sure nothing is wrong.

The main part needed from the I-10 running gear is the eccentric crank, rod and link. This conversion is set up with the idea that no new rivets are needed to complete the running gear.

Before the replacement rods can be set the hole in the eccentric crank must be filled since it is too big for the spectrum screw. This is done by tracing the opening on a piece of .010 styrene, then cut a little over sized. When close a technique I use is to press the crank on the cut piece fairly hard to get an exact impression of the opening in which the smashed parts can be trimmed off for a perfect fit. Then super glue is used to secure it in the opening.

Now a new hole can be drilled for the spectrum screw.

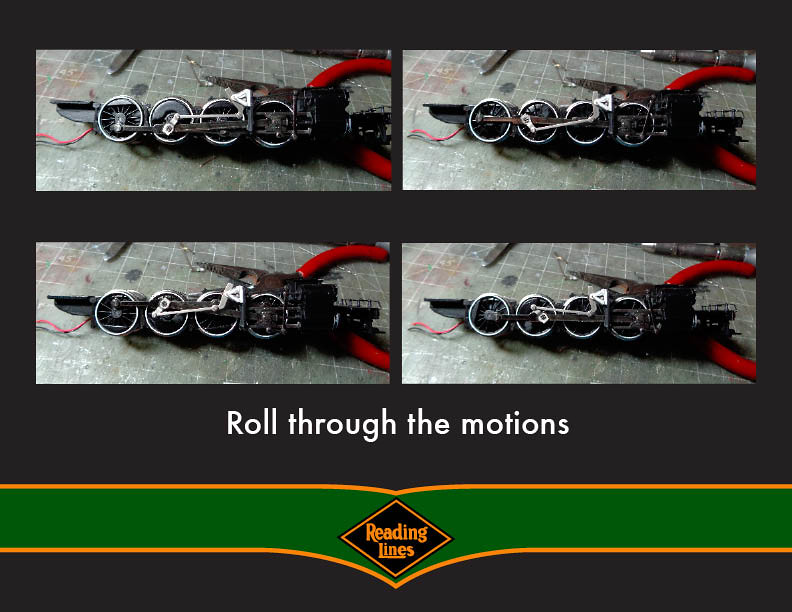

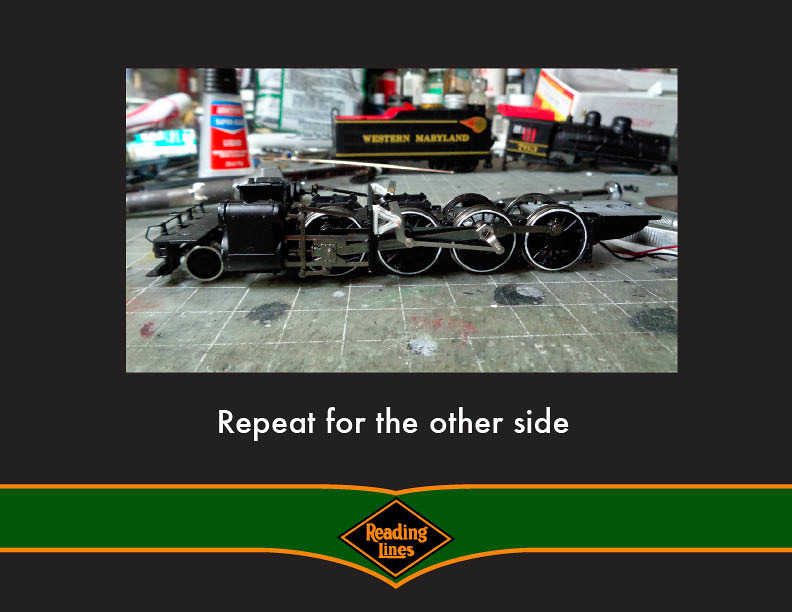

The valve gear can now be set with the spectrum hardware. I-9s had a forward facing eccentric crank, I don't have a specific degree for it, I just set it based on pictures. Once set roll the frame checking for any binding that may need adjustments, the images showing the rods in the south, west, north, and east positions.

Then repeat for the other side.

A variety of Reading Company operations related documents, etc. that may be of use in your modeling efforts.

A variety of Reading Company operations related documents, etc. that may be of use in your modeling efforts. A variety of Reading Company operations paperwork, such as train orders, clearance forms, etc. that will help you operate your Reading layout in a prototypical manner.

A variety of Reading Company operations paperwork, such as train orders, clearance forms, etc. that will help you operate your Reading layout in a prototypical manner. Public Timetables, Employe Timetables, and Rulebooks that provide much useful operational information.

Public Timetables, Employe Timetables, and Rulebooks that provide much useful operational information. Signs, billboards, and other FREE goodies for your use. We ask only that you help spread the word about The Reading Modeler!

Signs, billboards, and other FREE goodies for your use. We ask only that you help spread the word about The Reading Modeler!