Work continued with the cylinder heads. The cylinder faces are metal and were ground down a bit with a dremel about half of the total thickness the head use to be.

Then a new smaller head was made from .040 being sanded to a dome shape.

To make the bolts a strip of .010x.020 was cut into little squares and glued around the head, after the dome shape was centered and glued.

The installed views.

The shell was ground down with a dremel when the cylinders were, in short everything but the stack goes as well as the bands on the lower half.

Next I worked on the smokebox front and decided to use part of the original. Using the LED lights that came with the engine the wires go through a little hole in the shell and plug into the LED leads. To make it accessible for taking the shell on and off the smoke box front needs to be removable. I sanded everything off the front to the flat base and make the layers, 2 .040 and 1 .010. The .040 layers were sanded into dome shapes.

The layers glued together.

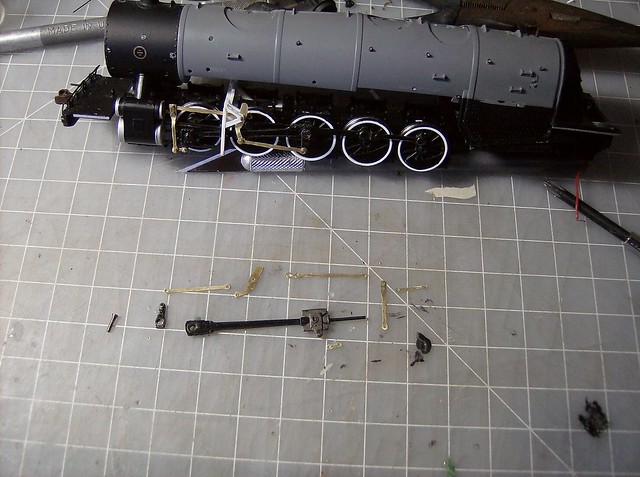

For some reason I jumped to the fire box before finishing the front but I'll get to that. The inner door hinges are .010x.040 strips, the one is cut a little short to fit the head light bracket. The outer hinges are .010x.040 on edge tapered down toward the inner of the smokebox front backed on the outside by a small piece of .040 styrene. The inner door latches are small pieces of .010x.020.

Here is the headlight in place matched up with the N-3 which is basically a shorter version of the same engine.

The firebox is just a width extension of the original by about 1/8" using the original cab floor as the width limit. It started with a frame of .040.

Then a piece of .010 was placed on each side oversized, trimmed down and sanded into smoothly into the boiler on the top. Also when sanding the corners are rounded.

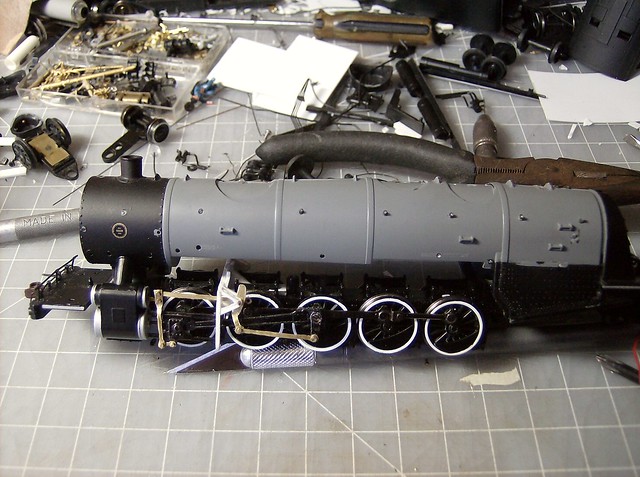

It was around this point I decided to use the original steam dome since it was basically in the right spot.

Then, putty.

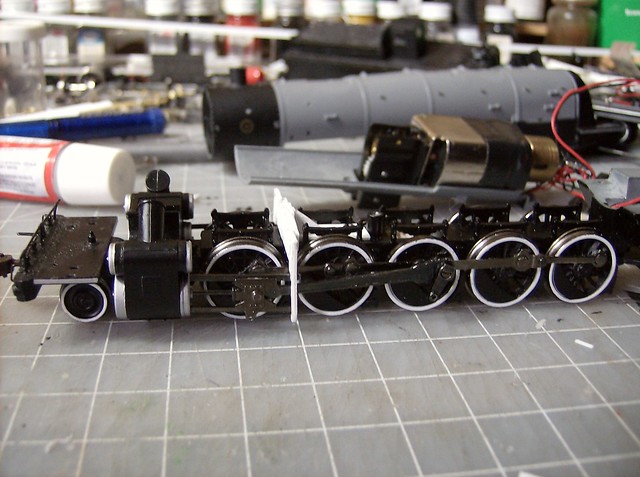

The tender started with the trucks being drilled out to fit on the existing frame which also needed a spaces of .040 to bump it up higher.

Then the original hardware is used. This is a dry fitting of just the trucks and pick ups not connected to the circut board.

To start the shell I wanted to make a base frame that snugly fit on the frame to keep the shell on, but first there were little nubs that needed to be ground off for it to sit flush.

The base frame with wire hole in the front.

Then the actual tender sides were glued to that frame which I made 7/8" high.

The top was fitted.

Then the coal bunker interior.

This was a new Idea to give the rounded top bunker edges more support by running rails between the fitted front and back. The front and back pieces were cut just a little skinner then the width of the tender to fit a .010 piece.

Then the top pieces were glued in place.

After all was set the 4 corners got sanded to be rounded. There will be a small coal bunker extension added but I want to get the cab in place to know just how high I want to make it.

Then I sanded the boiler down (a day after I set the putty) but there were a couple places that needed a little reapplication. So heres where is sits now.

A variety of Reading Company operations related documents, etc. that may be of use in your modeling efforts.

A variety of Reading Company operations related documents, etc. that may be of use in your modeling efforts. A variety of Reading Company operations paperwork, such as train orders, clearance forms, etc. that will help you operate your Reading layout in a prototypical manner.

A variety of Reading Company operations paperwork, such as train orders, clearance forms, etc. that will help you operate your Reading layout in a prototypical manner. Public Timetables, Employe Timetables, and Rulebooks that provide much useful operational information.

Public Timetables, Employe Timetables, and Rulebooks that provide much useful operational information. Signs, billboards, and other FREE goodies for your use. We ask only that you help spread the word about The Reading Modeler!

Signs, billboards, and other FREE goodies for your use. We ask only that you help spread the word about The Reading Modeler!